Laser drilling redefined: Pulsar Photonics’ RDX2Drill works in single-pulse mode

Drilling thick metal sheets precisely and efficiently

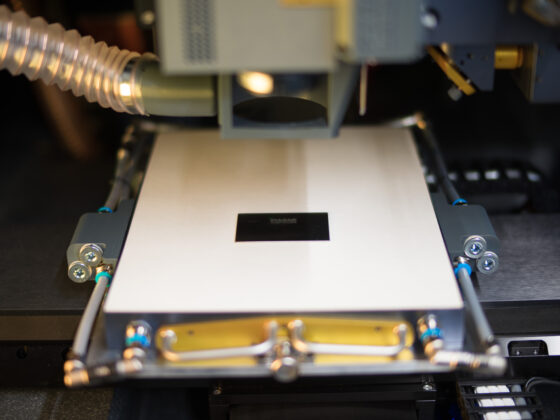

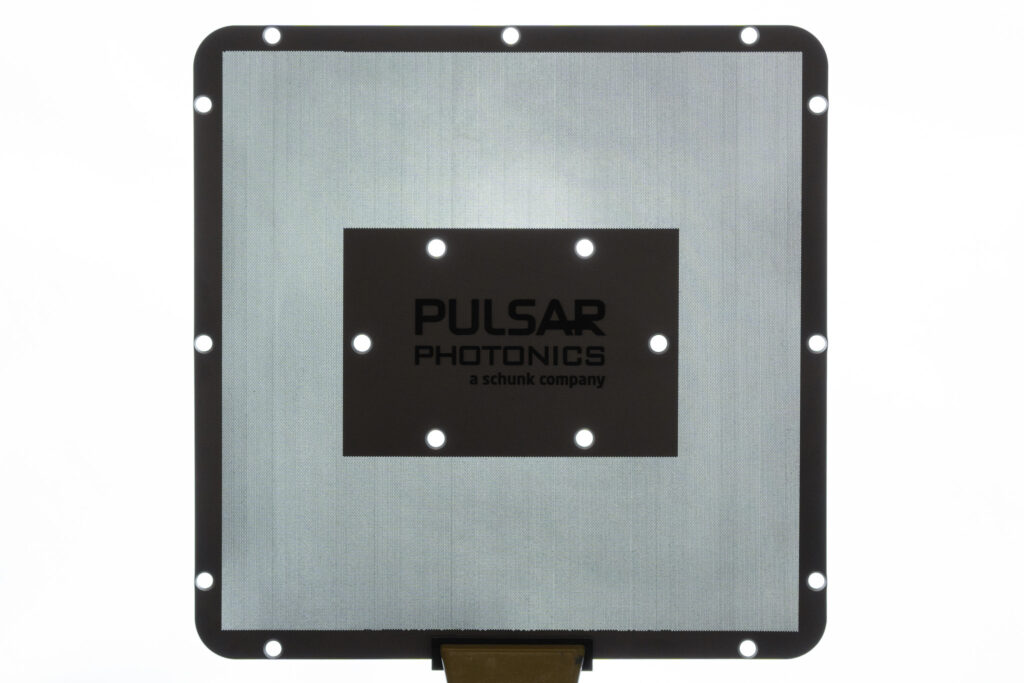

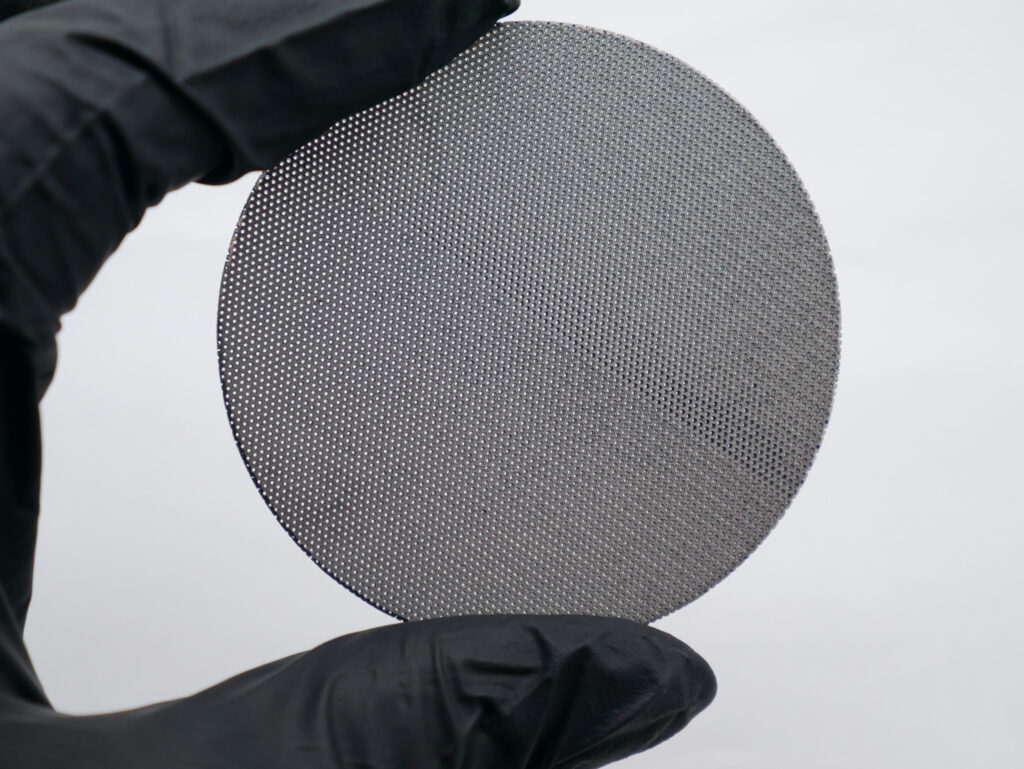

Pulsar Photonics uses the single-pulse drilling process in the new RDX2Drill series to precisely and efficiently “shoot” holes in thick metal sheets. The plus: Sieves or filters made of high-strength materials and thick sheets can now also be micro-drilled with the laser. Such filters can therefore withstand high pressures or the strongest mechanical stresses.

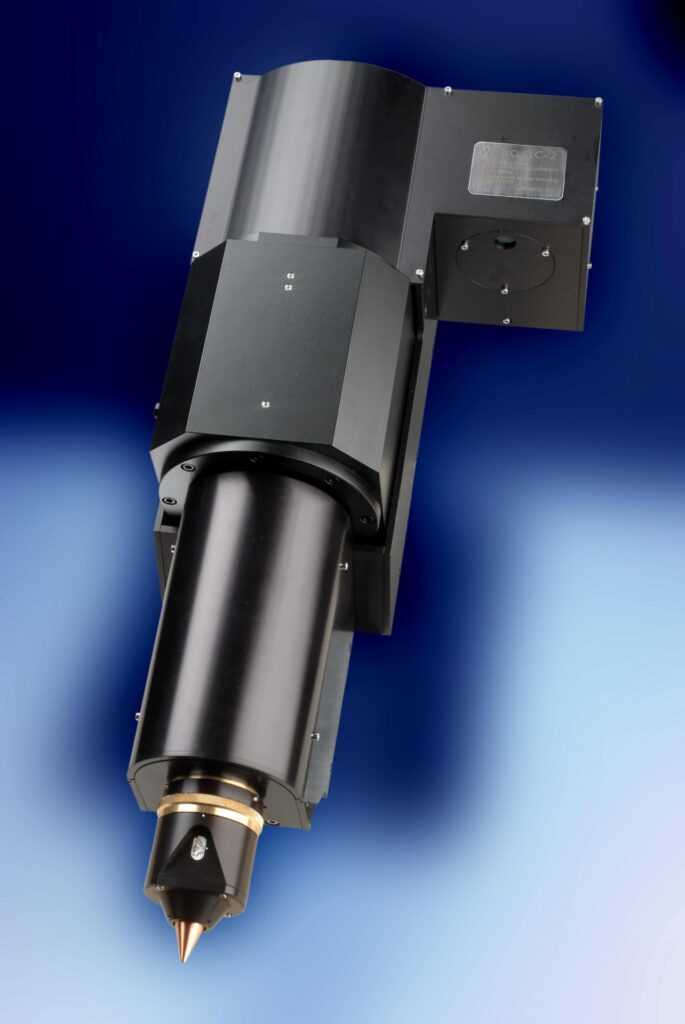

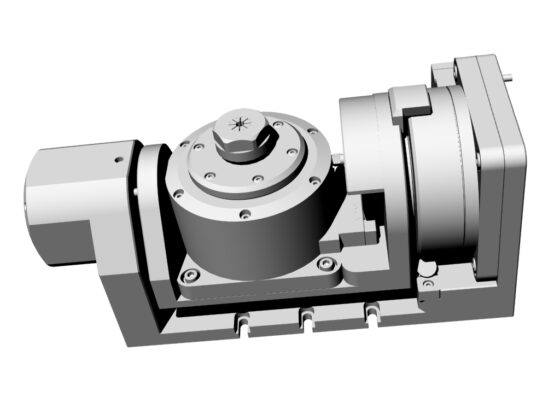

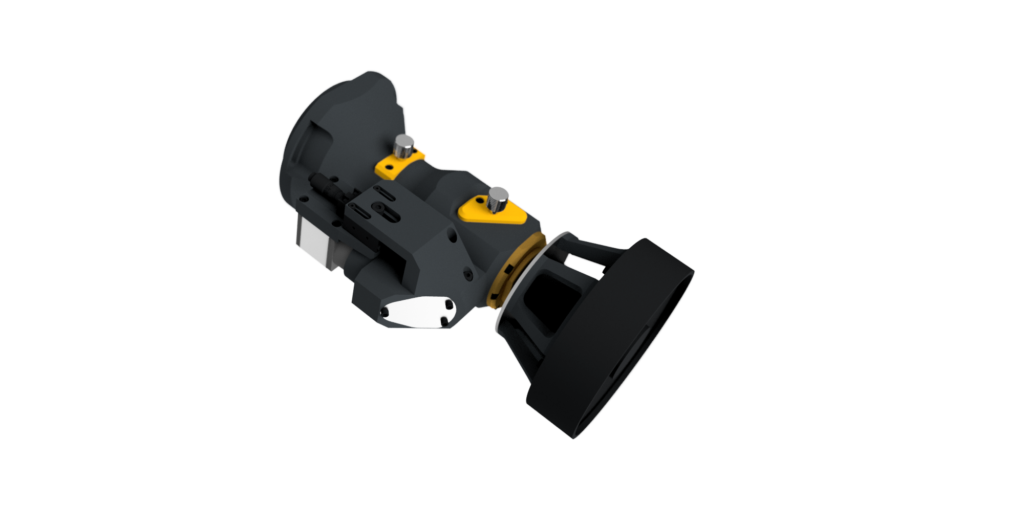

Pulsar Photonics GmbH from Aachen deliberately uses single-pulse drilling for its RDX2Drill machine series. “These are high-energy pulses that do not work in an ultrashort pulse cycle, as is usually the case, but last microseconds or even milliseconds,” explains Dr. Marius Gipperich, Manager Key Account & Business Development. “They therefore have so much energy that each pulse basically shoots a hole in the material.”

If the laser “shoots” 50 holes per second …

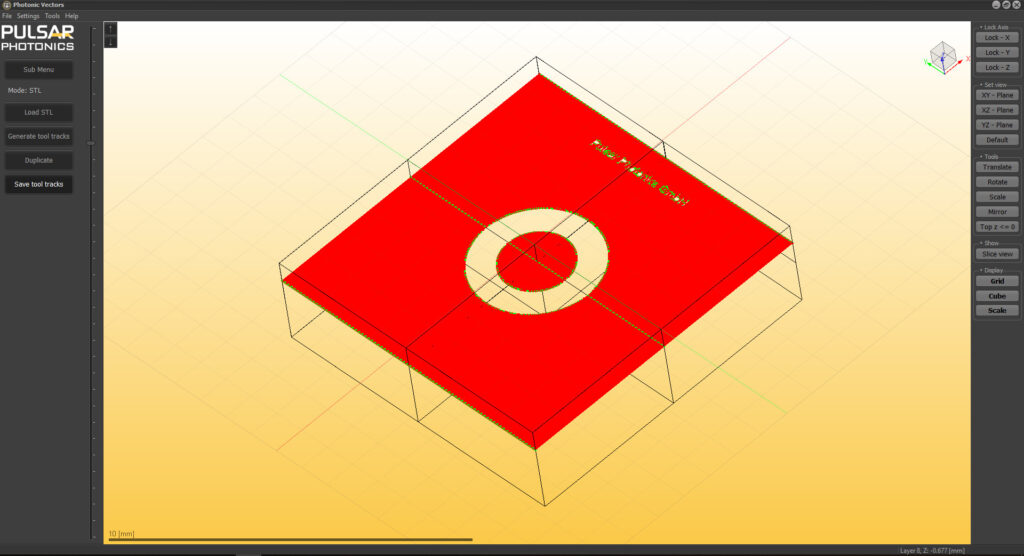

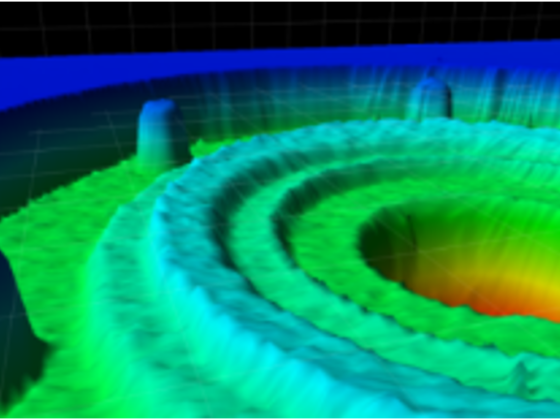

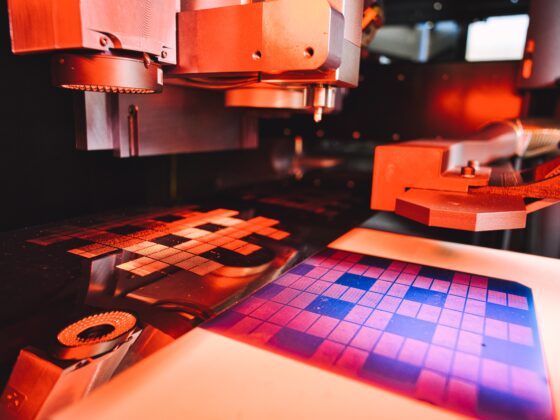

Although the process does not have as many pulses per time as the ultrashort pulse laser, the speed is still impressive. For example, one user is currently running a process with 1.5 millimeter thick stainless steel sheet metal in which the RDX2Drill is laser drilling 50 holes per second. In his opinion, this value can be increased even further. The new system can therefore drill up to hundreds of thousands of holes with diameters of 100 to 400 micrometers in metallic materials with a material thickness of 0.5 to 1.5 mm with the utmost precision. Gipperich: “The efficiency and costs, primarily in the production of holes with diameters of around 200 micrometers, clearly speak for our laser drilling.”

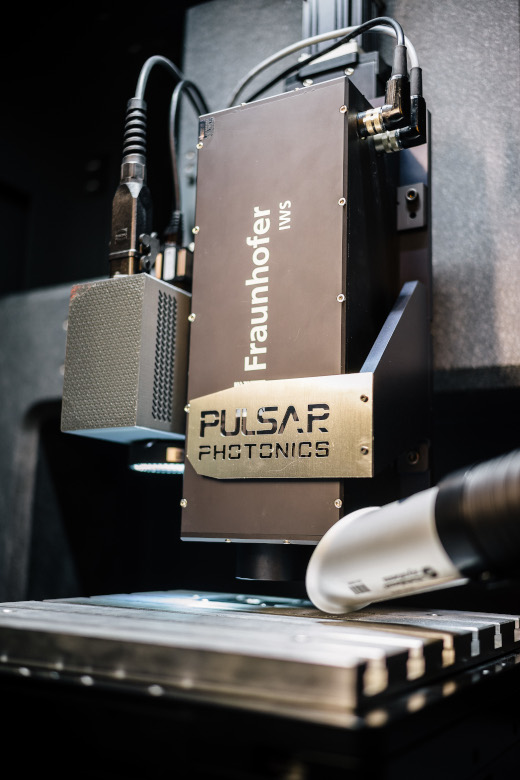

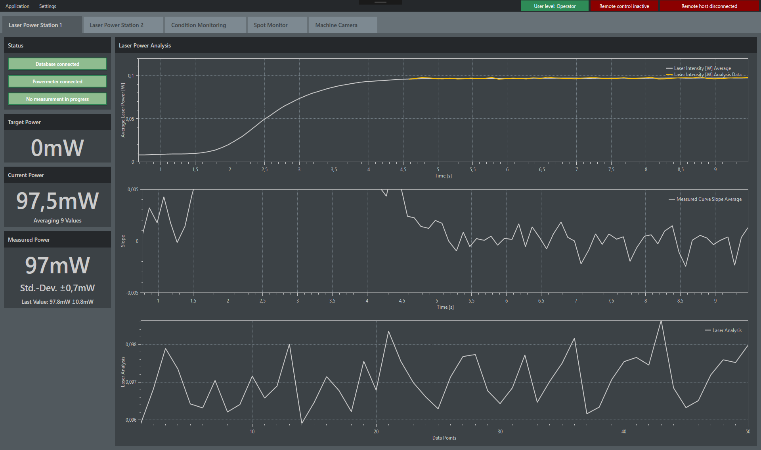

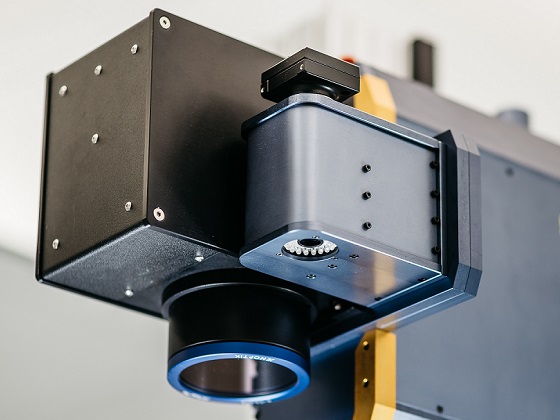

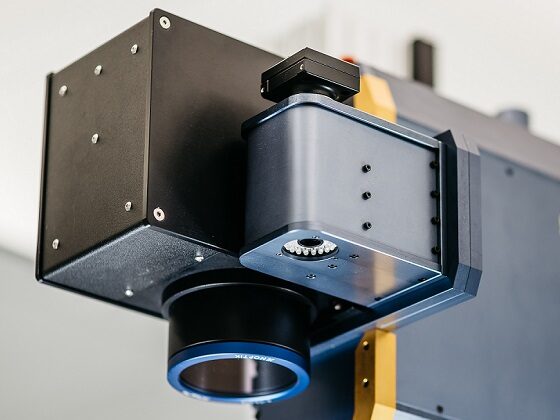

A QCW (Quasi Continuous Wave) fiber laser with an output of several kilowatts perforates workpieces with a wavelength of 1060 to 1080 nm (infrared). One of the strengths is the combination of flexible system technology from the modular system with individual software. Gipperich: “One of our unique selling points is the Photonic Elements machine control system, which we have developed, designed and perfected exclusively for laser processing.”

© Pulsar Photonics GmbH.

© Pulsar Photonics GmbH.

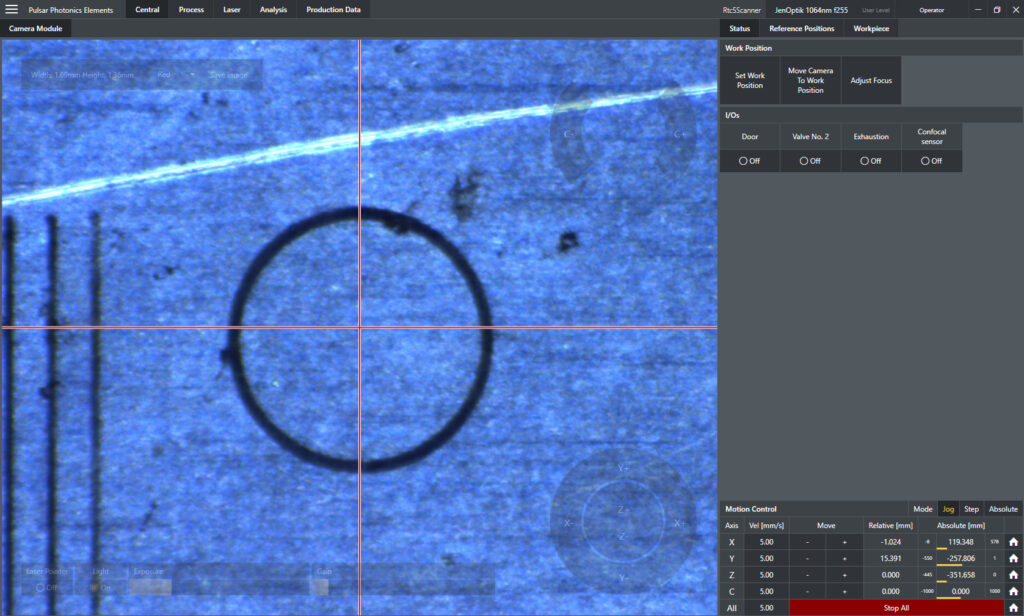

Special software only for laser processing

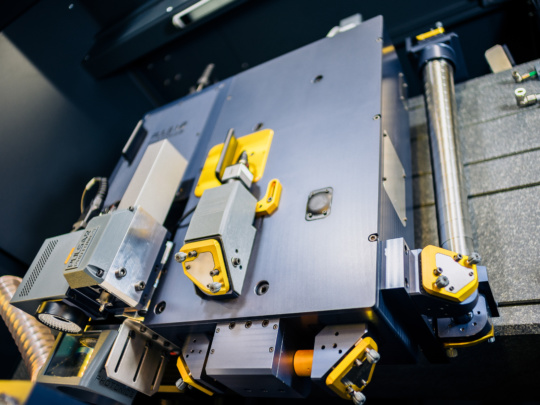

Photonic Elements enables precise control and optimized process management, increasing the precision and efficiency of laser drilling. The digital control also allows you to switch quickly and easily between different component variants. This is a particular advantage for sieves and filters with high material thicknesses, which are subject to high pressure loads and require precise, customer-specific drilling patterns. Introducing this process was a challenge, emphasizes Gipperich: “With this melt-based process, we have to remove several hundred grams of melt per component. For this reason, the systems are equipped with an enclosure that surrounds the process area. The majority of the melt is extracted, collected and disposed of safely.

© Pulsar Photonics GmbH.

Automatic focus tracking instead of component distortion

The process generates a lot of heat in the component, which leads to distortion. Automatic focus tracking, which compensates for component deformations caused by thermal stress, for example, has proven itself as a countermeasure. With the purchase, the user is entering a complex technology that requires special training from the Aachen-based company: Nevertheless, it is worth getting started because the new RDX2Drill series is suitable for many applications: for example, sieves and filters for waste water filtration, hydrogen production, recycling and energy generation.

© Pulsar Photonics GmbH.

Downloads

Pulsar Photonics

Pulsar Photonics GmbH is an innovative high-tech company in the field of laser technology. The company’s range of services includes the laser application center, system engineering with software development and the laser system technology division.

Since its foundation, the company has been working intensively on scaling approaches for production. For customers, it offers exclusive services ranging from professional application development and ramp-up to the construction of automated production machines with service and know-how transfer. Pulsar Photonics continuously invests in its own production capacities for single part and series production with (ultra) short pulse lasers. The core processes are structuring, drilling and precision cutting.

The company was founded in 2013 as a spin-off of the Fraunhofer ILT in Aachen, has its headquarters in Aachen and operates three production plants. Pulsar has been part of the Schunk Group since 2021 and currently has around 100 employees.

Press Contact

Sonja Wichert

E-Mail: wichert@pulsar-photonics.de

Pulsar Photonics GmbH

Alte Würselener Str. 13, 52080 Aachen

Website: www.pulsar-photonics.de