Drilling system for single-pulse drilling with high-power QCW fiber lasers

Processing area up to

400 mm x 400 mm x 400 mm

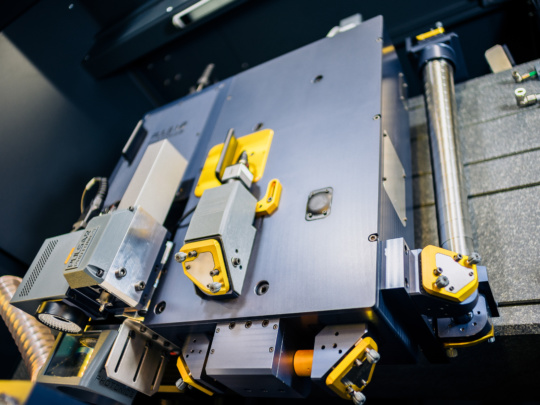

Integrated extraction unit for removing melt particles

LASER Drilling machine: MACHINE for laser drilling of metallic sieves and filters

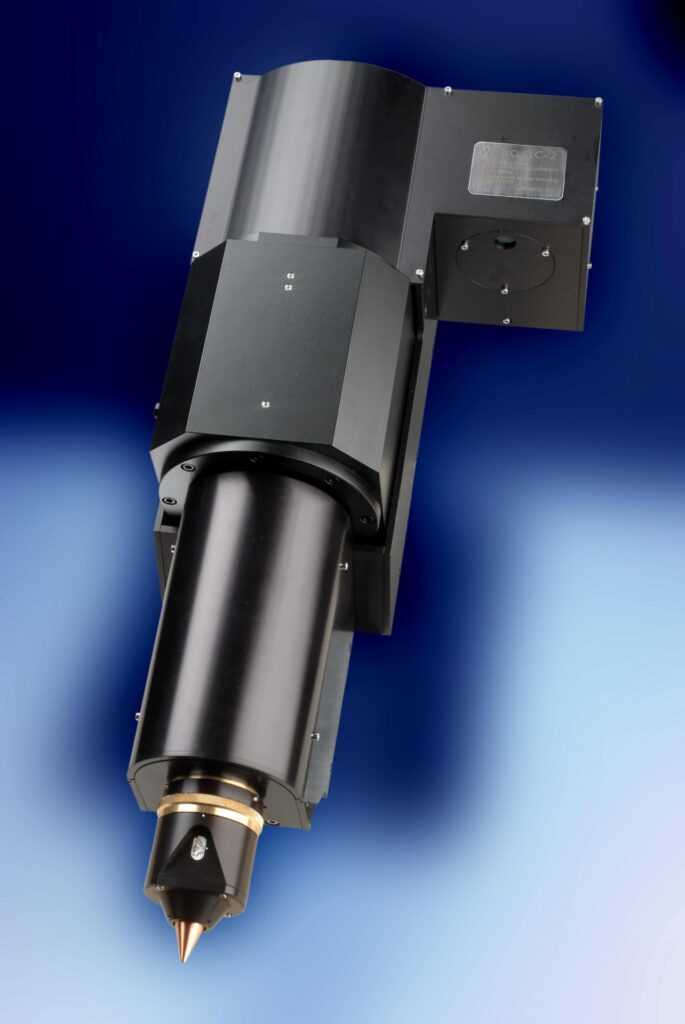

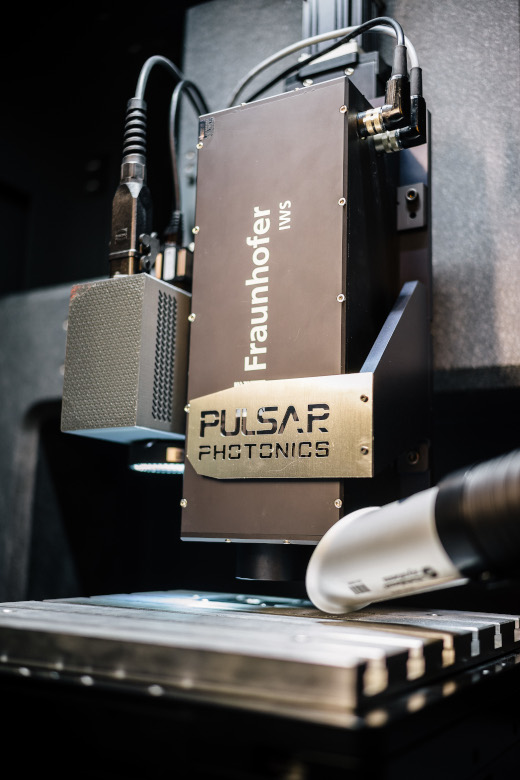

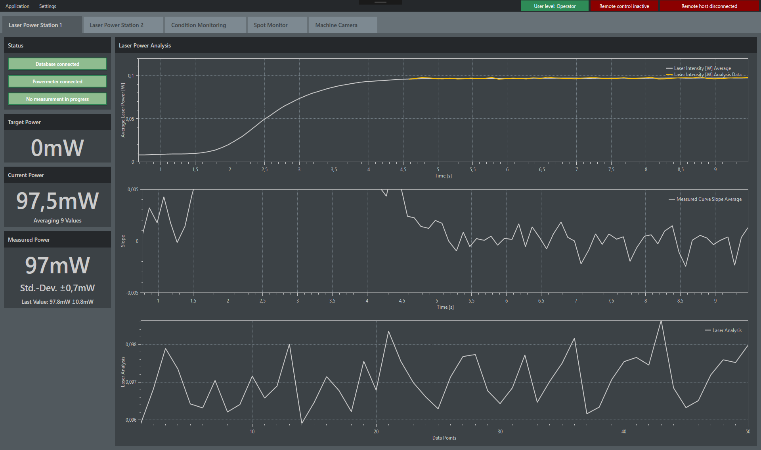

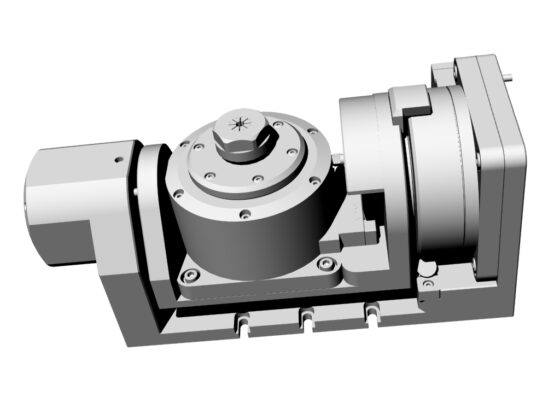

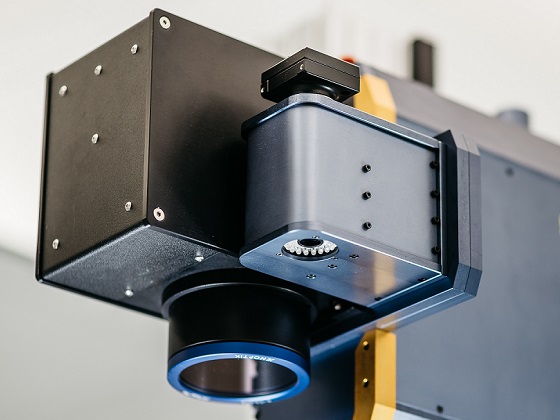

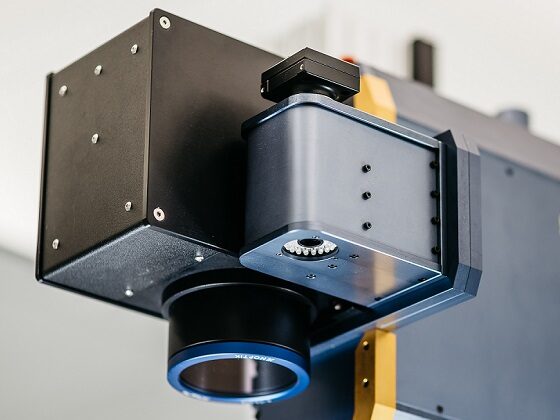

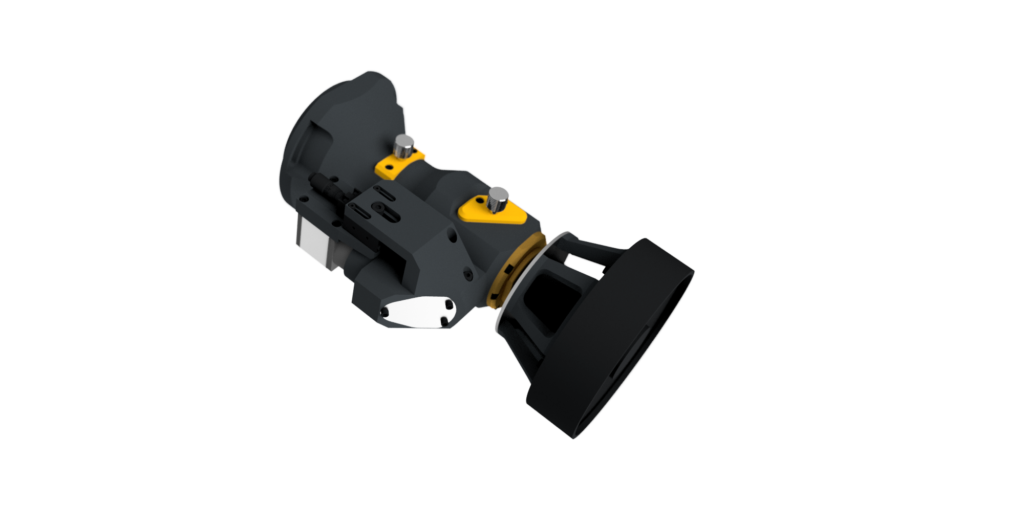

The RDX2Drill is a configuration of the RDX2Fiber machine series and addresses melt-dominant laser drilling with fiber lasers.

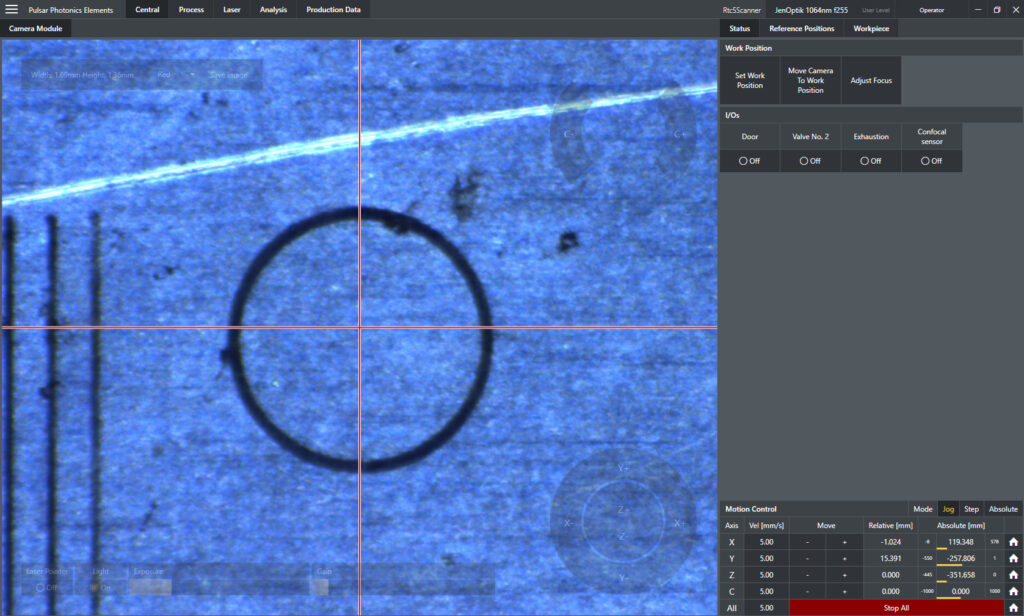

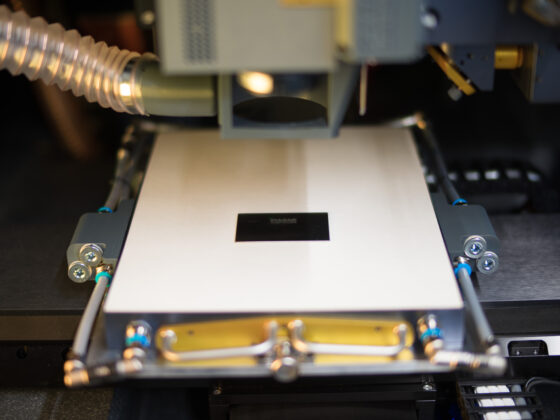

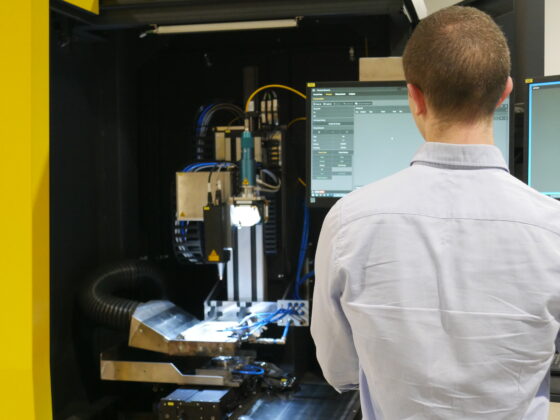

A fiber laser, a drilling process head (fixed optics) and a fast xyz axis system for positioning workpieces under the process head ensure highly productive drilling processes. Measuring technology in the form of a camera and a laser measuring probe enables both the precise positioning of the workpiece before drilling and the monitoring of component deformation during the highly thermal process.

The deformation is compensated for by automatic focus tracking. By integrating an extraction unit and a process enclosure above the workpiece, melt particles can be reliably removed during processing.

Areas of application

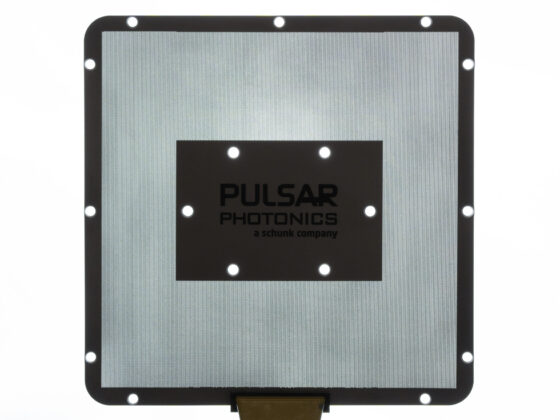

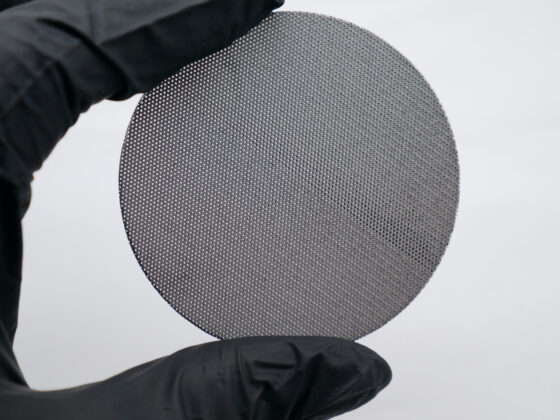

The RDX2Drill is designed for the production of metallic sieves and filters using melt-dominant laser drilling.

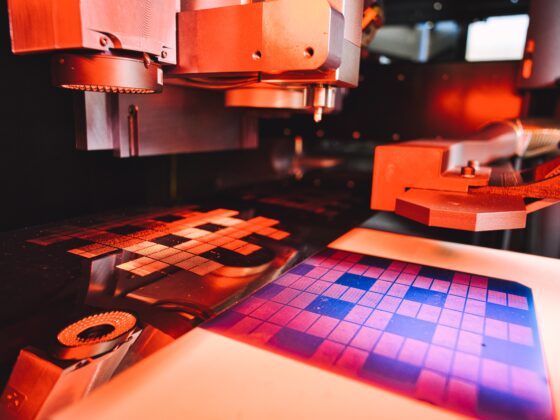

QCW lasers are generally used. These have a peak pulse power in the multi-kW range, while the pulse durations are in the order of a few microseconds or often even milliseconds. The pulses have such a high pulse energy that they are suitable for single-pulse drilling. This means that drilling rates of more than 50 Hz can be achieved even with thicker sheets.

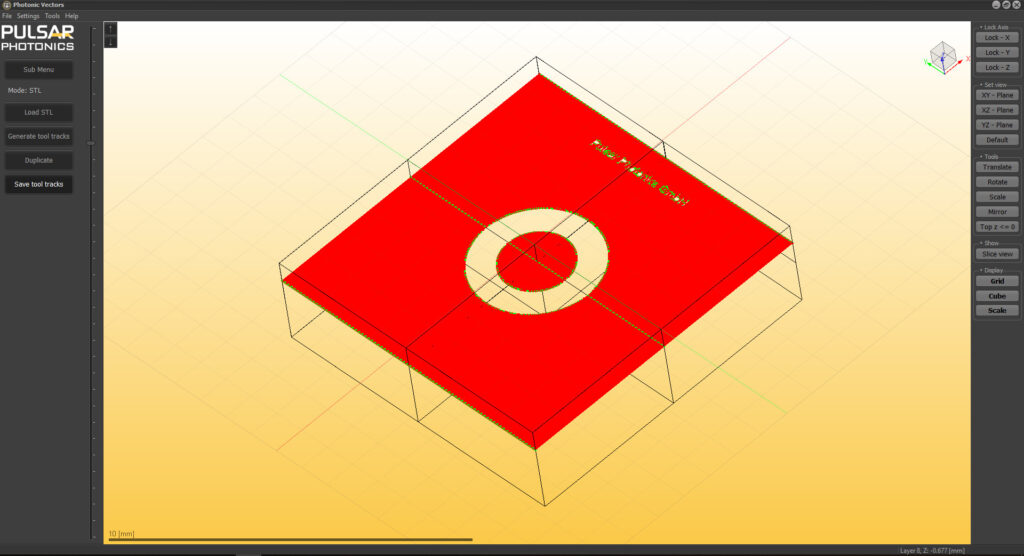

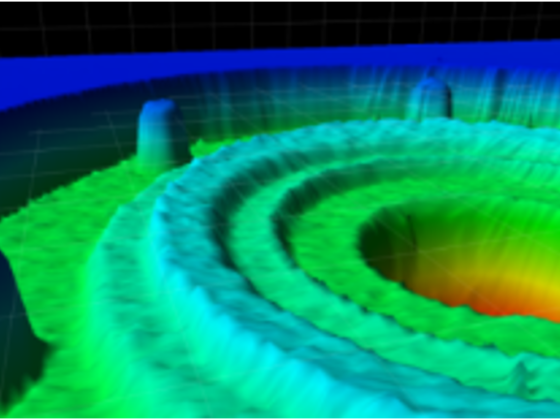

With this process, the RDX2Drill can be used to drill holes with a diameter range of 100-400 µm in stainless steel sheets with a material thickness of up to 2 mm (see Laser-drilled screens). Thanks to the software-based control, almost any drilling pattern can be realized.

In addition to the laser process, the handling of the melt discharge plays a decisive role. For a typical filter with a material thickness of 1.5 mm and a diameter of around 200 mm, for example, several hundred grams of material are removed by drilling. Melt deposits on the component are minimized on the RDX2Drill thanks to intelligent process control.

Picture Gallery

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales