Laser machine manufacturing for material processing

Pulsar Photonics produces turnkey production machines for laser micromachining as well as RDX laser machines for your application development and small batch production.

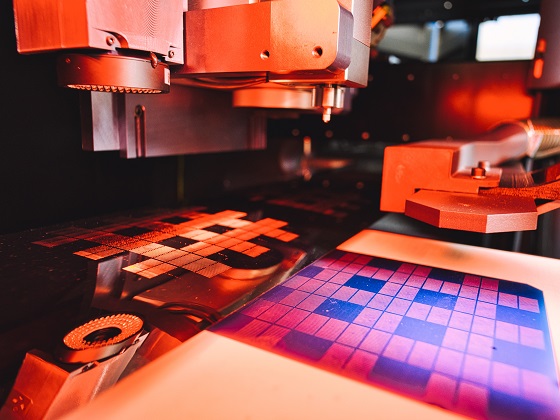

Typical applications of the machines are

- Laser microdrilling (ceramics, metals, plastics, glass)

- Laser microstructuring (tools, thin-film processing)

- Laser fine cutting (ceramics, plastics, thin metal foils)

- Laser microwelding

- and the functionalisation of surfaces.

You can find examples of the diverse areas of application for our laser systems in the Application areas section.

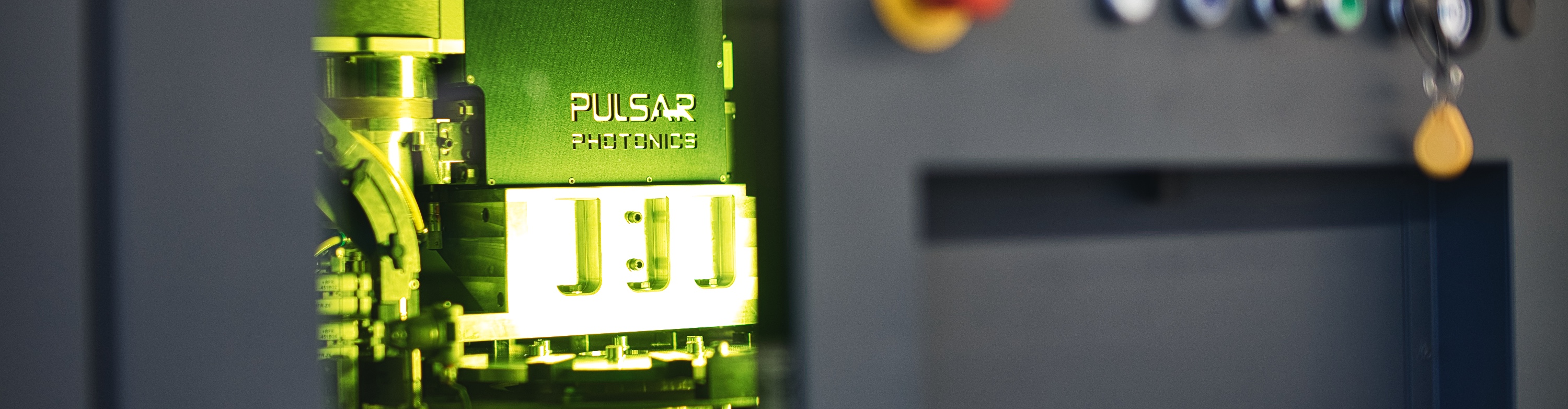

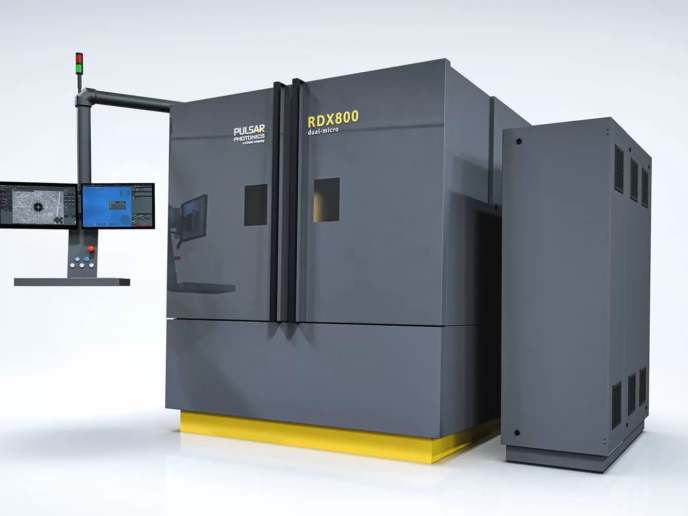

They can be recognized from afar by their distinctive design. But above all technologically our laser machines have a lot to offer: The production machines shine with high throughput and clever process technology. And our self-developed RDX machine platform has been setting new standards time and again since 2016, for example when it comes to the use of high-power beam sources for material processing with ultra-short pulse lasers or the integration of beam shaping systems.

Have you already defined your production task? Then the rubric production machines something for you.

Would you like to push the boundaries of micromachining and push your own development?

Then the RDX500 or RDX800 is the right choice for you!

Are you looking for a compact system for fibre laser processing? Then take a look at our RDX2FIBER

Our Laser machines

RDX 500

The small-format RDX500 laser machine is always a good solution when precise and defined micro-processing without compromising quality is required.

P1000 automatic

Production machines are different. Process capability and availability are required here. We accompany you from the pilot series through to ongoing production. For sure.

Machine software

Today, the software solutions of the Photonic X Suite make the digital difference and determine the usability of the technology.

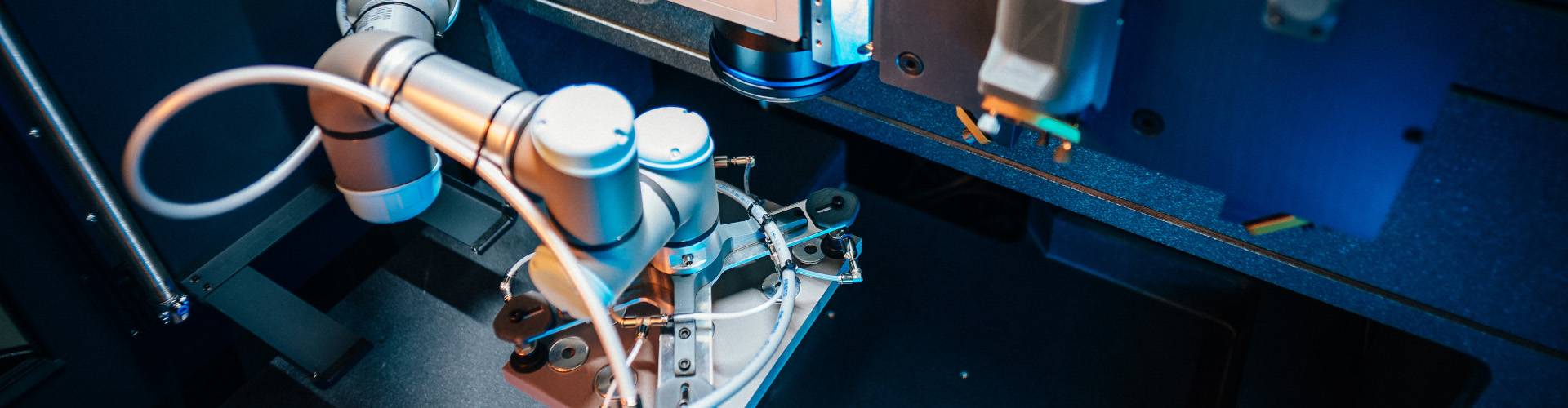

Machinecomponents

- Machine frame with enclosure for laser class 1, movable operating terminal with two screens and external control cabinet

- Machine bed made of polymer concrete or granite to dampen vibrations

- High-performance axis system with up to sub-micrometre precision

- Application-adapted laser beam source (ms, ns, ps, fs)

- Processing head e.g. scanner, fixed optics

- Machine-integrated measuring technology including camera systems, distance sensors, beam position stabilisation, condition monitoring system, CAM software for generating machining jobs;

- Machine control software with extensive functions and application-specific GUI

- Extensive expansion options, including suction, clamping systems, MicroScan, beam shaping systems, software features, etc.

- Professional service remotely and on site

WhyPulsar Photonics?!

- Long-standing laser process competence

- High-quality components and modular approach

- Increasing process efficiency through intelligent beam shaping and process optimisation

- Flexible adaptation of all systems involved to increase production quality and efficiency

- Flexible design: integration of different processing heads, individual workspace, integration of third-party components and systems

- Application-specific machine control software

- Integrated measuring technology for quality assurance in the machine

- Complete solution from application development to series production

- Extensibility: integration of new software tools or modules from Pulsar Photonics

Your Contact Person for sales

Louisa Draack

Technical sales