Every material can be machined with the highest precision and without thermal damage

Minimum achievable structure sizes

Standard: 10 μm lateral, 0.5 μm axial

Optimized: 2 µm laterally, 0.1 µm axially

Most precise laser process in micromachining

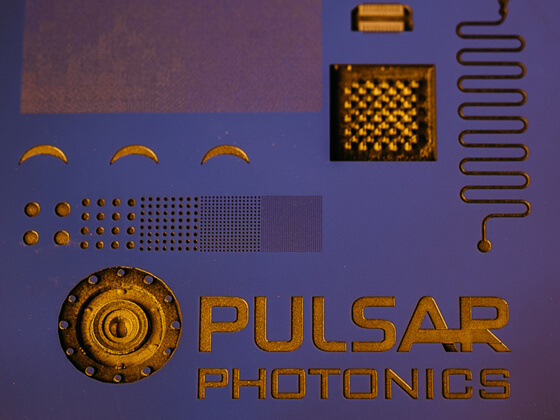

Laser microstructuring with the highest precision

Laser processing with an ultrashort pulse laser allows surfaces to be microstructured with very high precision.

Ultrashort pulse laser evaporate the material in focus due to the very high light intensities. Melt or processing residues cannot be found on the work piece, which makes the processing clean and post-processing-free.

The micromachining by laser ablation therefore has a high technical potential and is already used in a wide variety of areas.

The laser is suitable for micrometer accurate machining of tools and ceramics, for the roughening of materials for bonding or joining processes and also for the functionalization of surfaces like the friction minimization or resistant marking .

There are no limits to the type of microstructuring and the micrometer-accurate introduction of individual structures or even a full-surface structuring of components is possible.

LASER MICROSTRUCTURING: OUR STATISTICS

Highest depth resolution of machining

Full-surface functionalisation of a series of

Longest process time on the machine

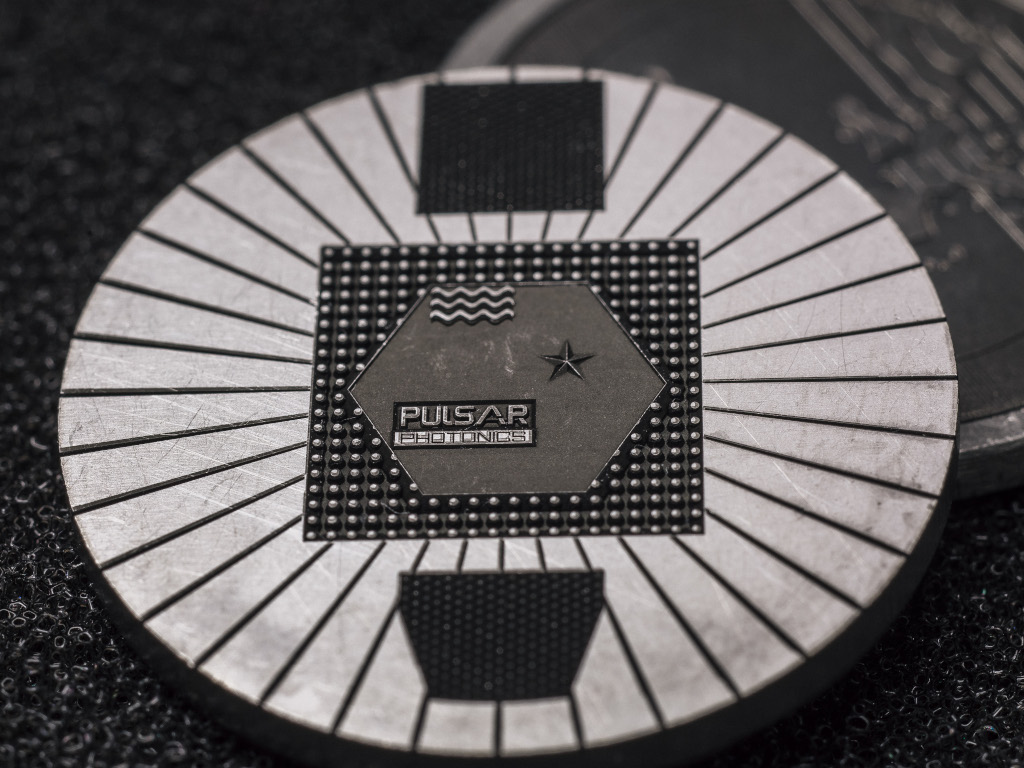

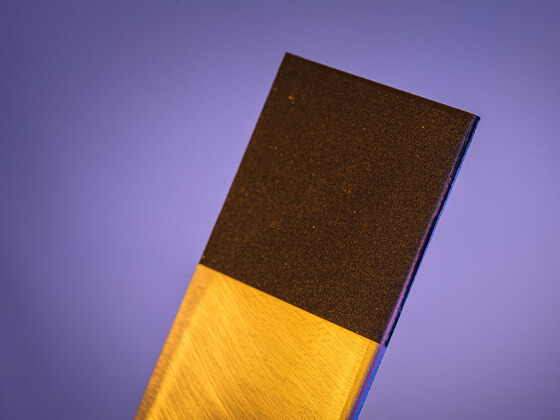

Tool machining – with ultrashort pulse lasers

Laser microstructuring of stainless steel and hard metal for the production of replicative tools

Laser microstructuring has increasingly established itself as a process for tool technology.

In addition to maximum geometric and material flexibility, the main advantages of laser structuring are the small structure sizes and surface roughnesses that can be achieved.

In addition, the fully digital process chains allow fast design changes with a significant impact on production flexibility.

Achievable qualities

- Structure resolution : Typ. from 10 µm

- Surface roughness: Typ. Ra = 1 µm, smaller roughnesses by laser polishing

Applications

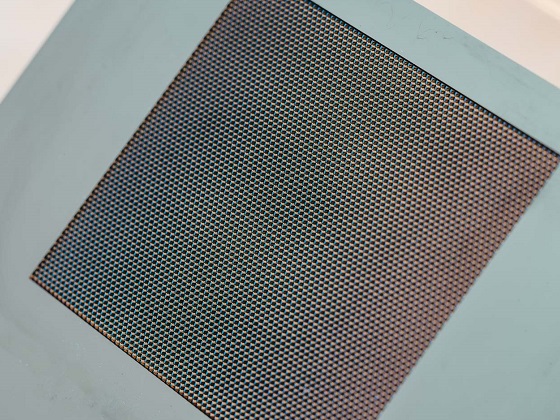

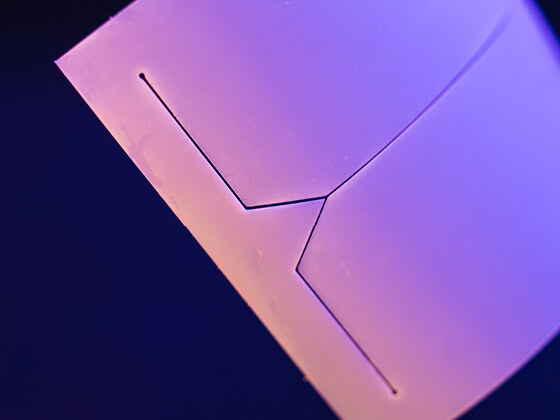

Processing of Ceramics, glass & polymers

Ceramic, glass and plastic processing

The very high light intensities that occur during micromachining with ultrashort pulse lasers allow materials to be machined where mechanical or other laser processes reach their limits.

This means that plastics can be cut cleanly and without carbonisation using the ultra-short pulse laser. Ceramics and glass can be drilled, structured and cut without thermal damage of the materials This results in new degrees of freedom in electronics and medical technology.

Achievable qualities

- Materials : Ceramics, glass, polymers

- Material thicknesses : 5-300 μm

- Structure resolution : Typ. from 10 μm

- Bore diameter: < 10μm – 300μm

Applications

All you need to know about laser Micro structuring

Learn more about laser micro processing

for industrial applications.

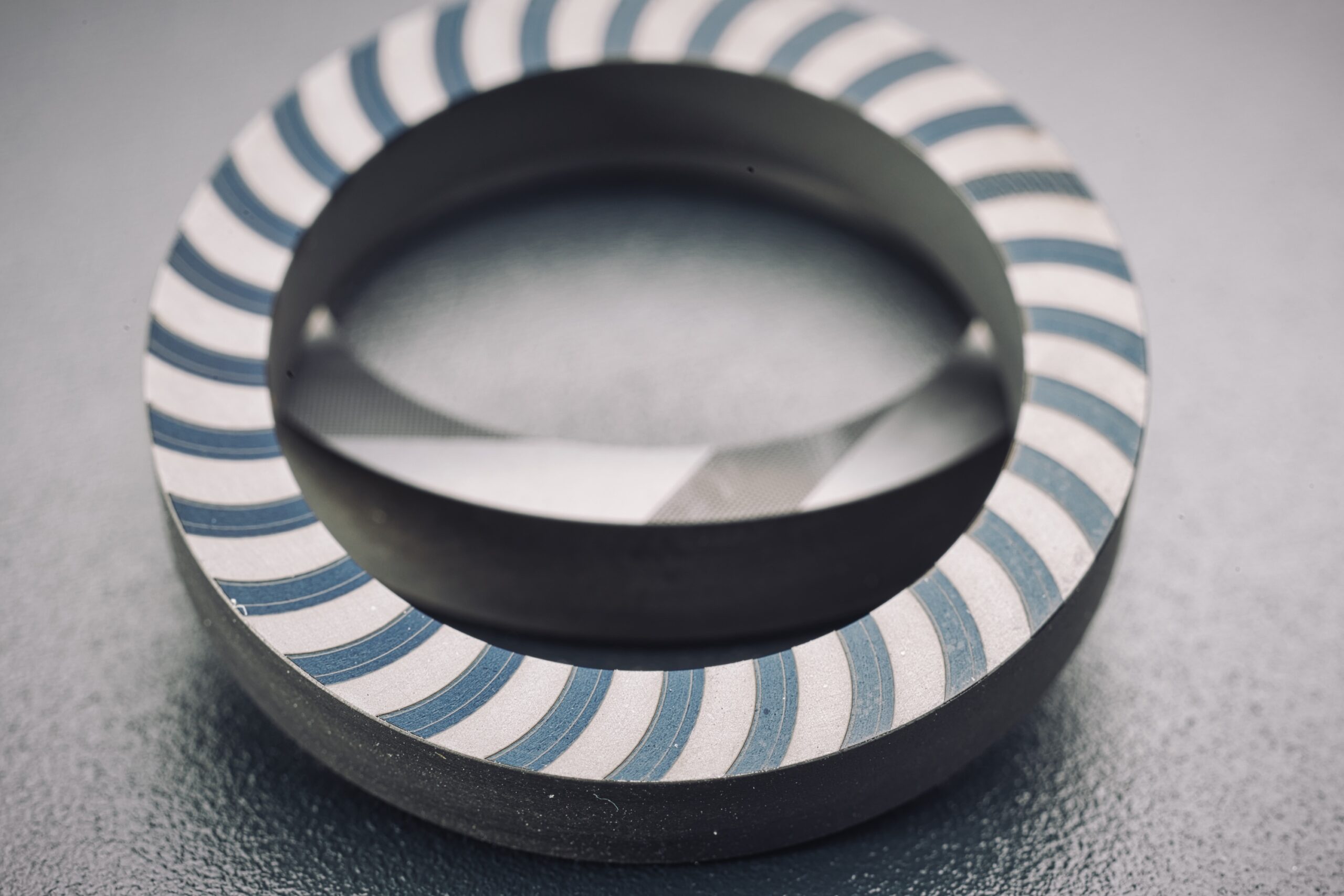

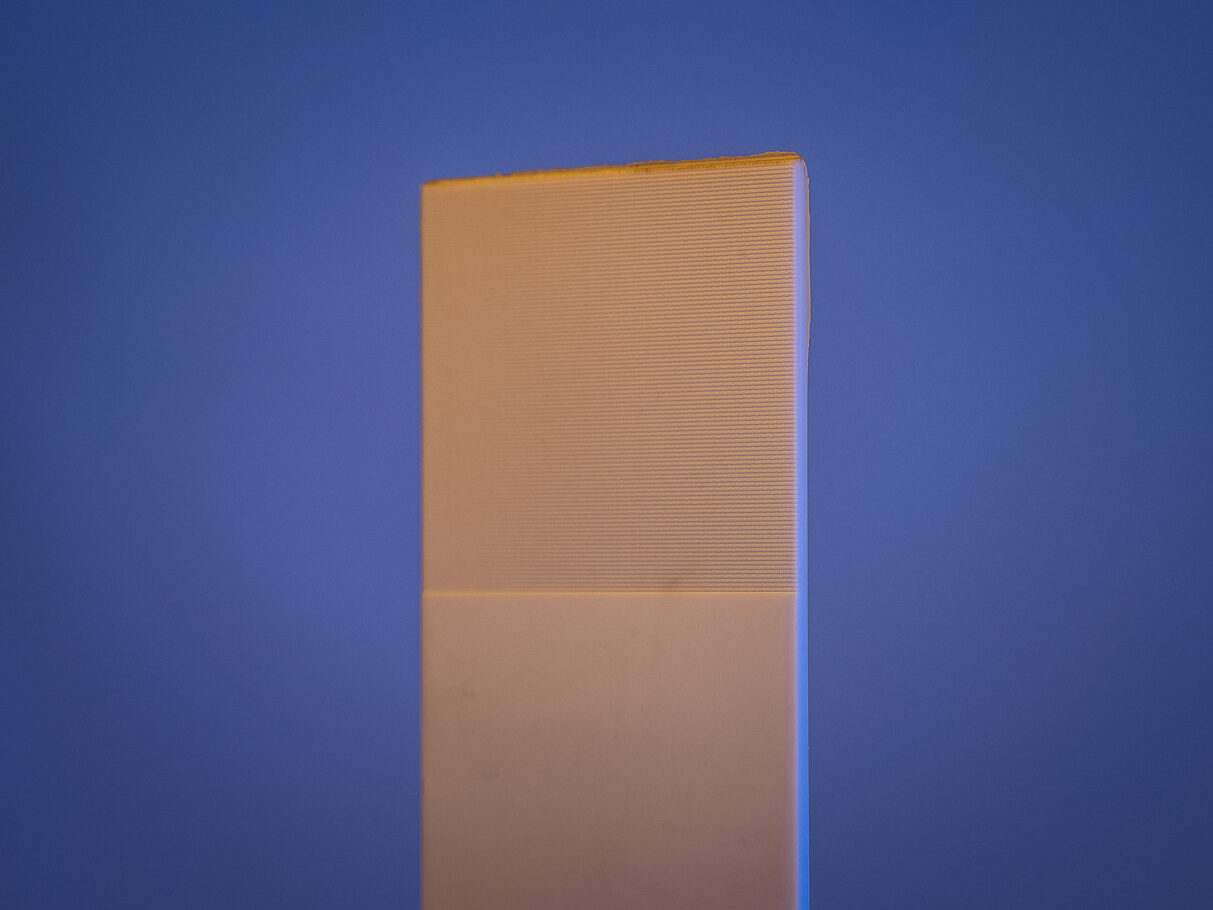

Roughening through laser structuring

Roughening by laser structuring

With the use of an ever greater variety of materials in e.g. electronic products joining processes dissimilar materials (such as metal-plastic compounds) are becoming increasingly important.

Laser processing allows the targeted roughening or structuring of partner surfaces. This leads to an optimization of hybrid joining processes .

Optimisation of joining processes

Metal surfaces in particular can be used with the laser undercut structures Mistake. These enable a special solid metal-plastic connection with shear strengths of up to 75% the tensile strength of the plastic material.

Different surface topologies can be set depending on the requirements of the component.

Applications

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales