Laser contract manufacturing

Pulsar Photonics is a competent partner for application development and contract manufacturing with ultrashort pulse lasers. In our job shop, every day we develop new laser processes for our customers on our own laser machines and support them from feasibility to product development and series start-up through to large-scale production.

OUR Laser processes

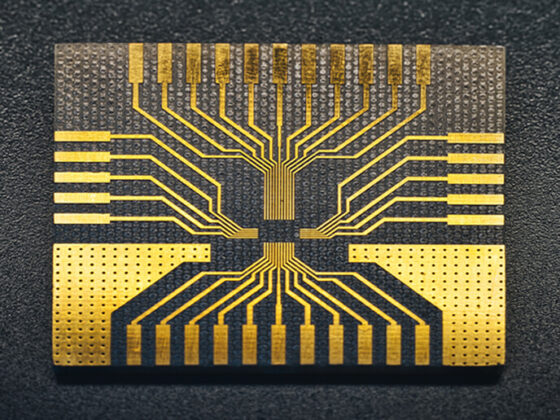

Laser micro drilling

Micro-drilling with laser radiation enables contactless and force-free machining of all materials with high precision.

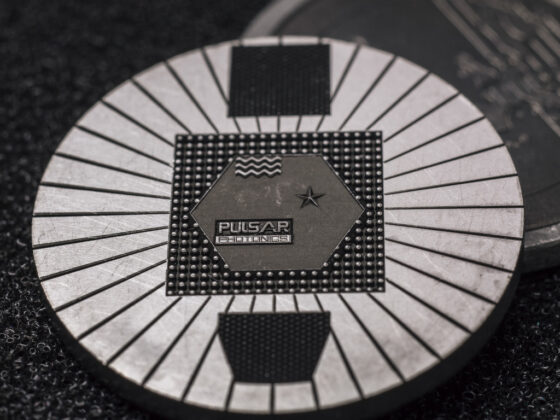

Laser microstructuring

Laser processing with an ultrashort pulse laser enables the microstructuring of surfaces with very high precision.

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales