Sustainable, precise and ultra-short: Pulsar Photonics relies on laser micromachining on an XXL scale

1000 laser beams in parallel swing

Aachen, June 19, 2024

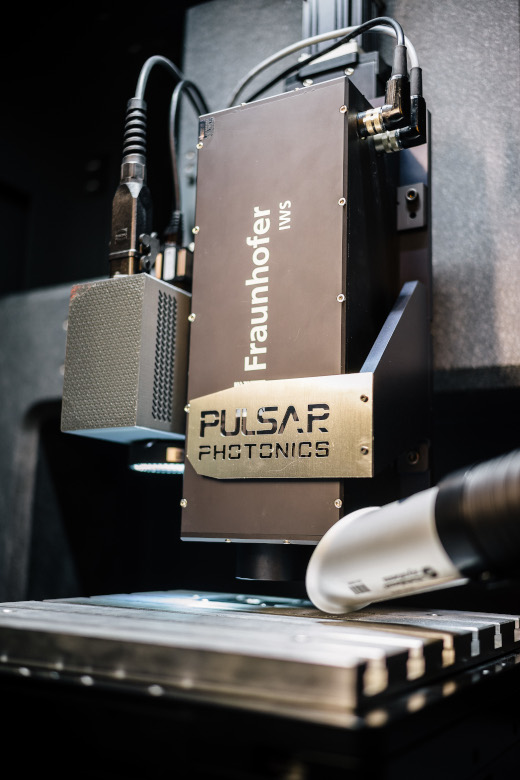

Pulsar Photonics GmbH from Aachen is continuing to develop laser micromachining: a system with an ultrashort pulse laser is currently being built that structures surfaces of more than ten square meters precisely and sustainably. In future, the scaling concept will even allow surfaces ten times larger to be processed using thousands of laser beams. “We’re not the only ones doing large-area laser micromachining,” explains Dr. Joachim Ryll, Managing Director of Pulsar Photonics. “But our approach is unique. Our aim is to structure surfaces in parallel and individually on a single large system.”

This is particularly relevant as the demand for surface structuring without chemical substances is increasing. This is due to increasing environmental restrictions and regulations that limit the use of chemicals. The ultrashort pulse laser (USP laser) offers a sustainable alternative for this. Until now, USP lasers have mainly been used for small-area applications, but there are already solutions that can effectively process surfaces in the square meter range for flat glass, film substrates and embossing rollers.

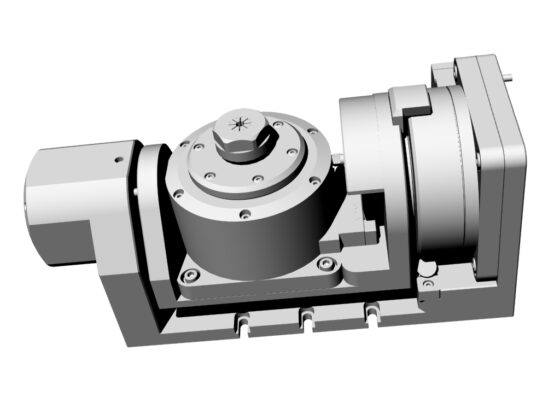

Up to five workstations in parallel use

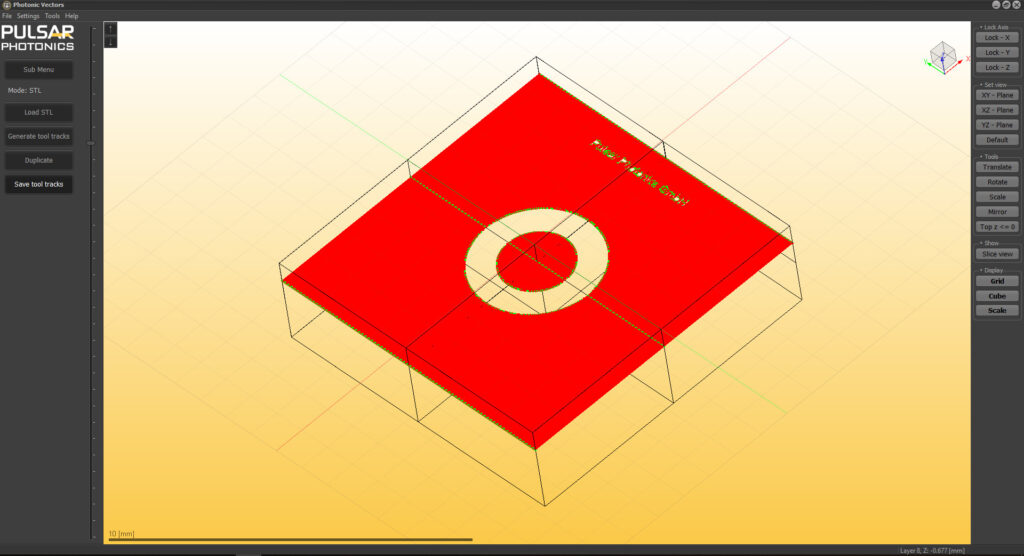

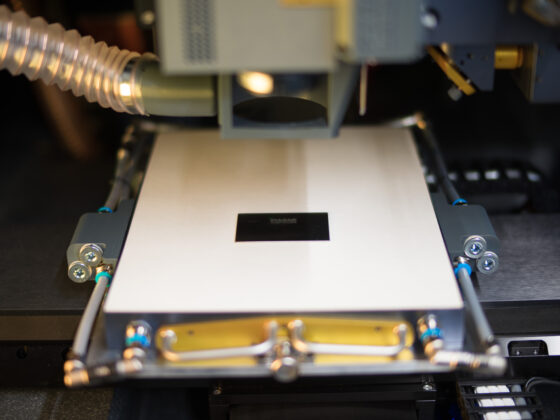

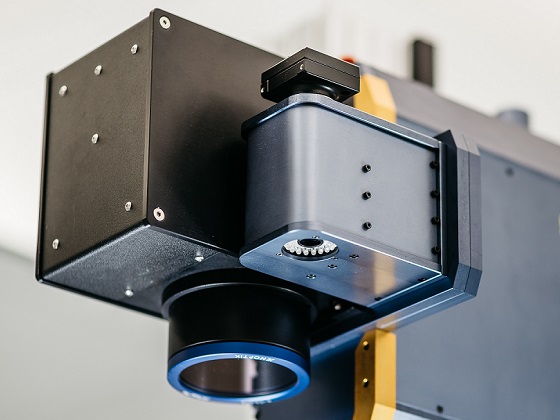

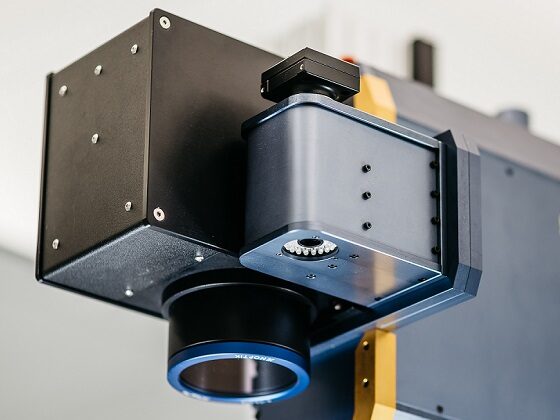

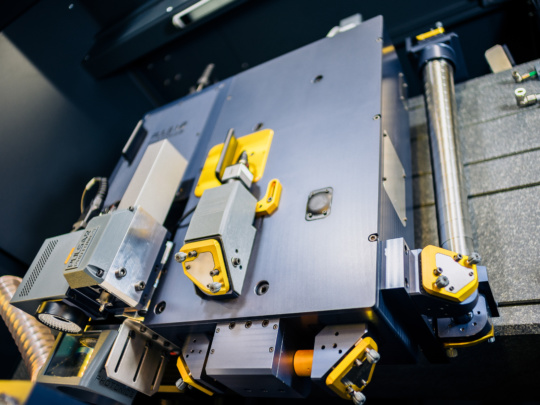

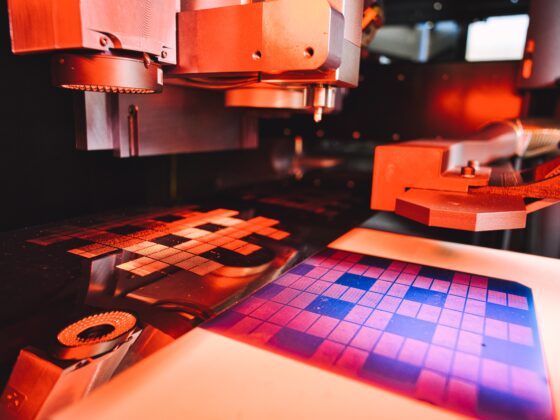

The Aachen-based company relies on a special kind of bridge technology for its RDX2800 gantry system: its machine modules are based on a modular system. Each module can precisely process flat components of up to 2.5 x 1.5 meters with USP lasers. Pulsar lines up several modules in a row and can therefore process larger components that are well over 10 m². Within a machine module, several work stations enable both individualized single-beam and multi-beam processing. A total of more than a thousand laser beams can be used simultaneously. In the EU infrastructure project NextGenBat, the Aachen-based company has already shown how the productivity of laser micromachining can be significantly increased. They developed a roll-to-roll system that dries and structures electrodes for lithium-ion cells. The “MultiBeamMultiScanner” optics split the laser power into several partial beams in order to work more efficiently. The company is now taking the first step towards a modular system with a pilot customer. “The industrial implementation on a large scale is the special attraction,” explains Dr. Ryll. A system is planned for the pilot customer in which several interlinked workstations will precisely roughen and structure the surface of flat components measuring over ten square meters using USP lasers and multi-beam technology with several partial beams.

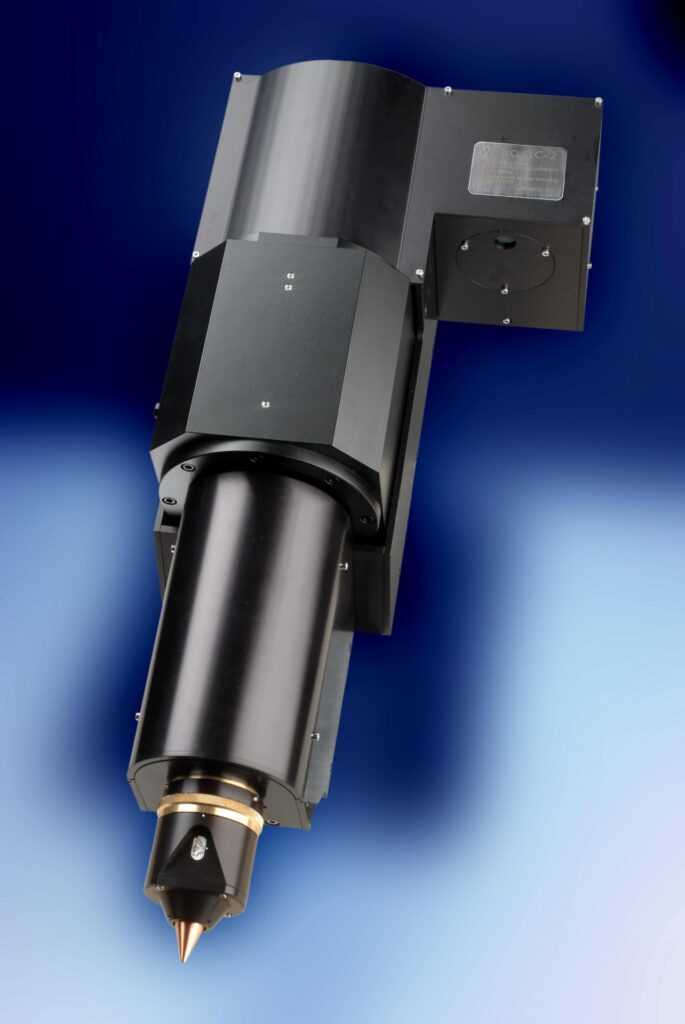

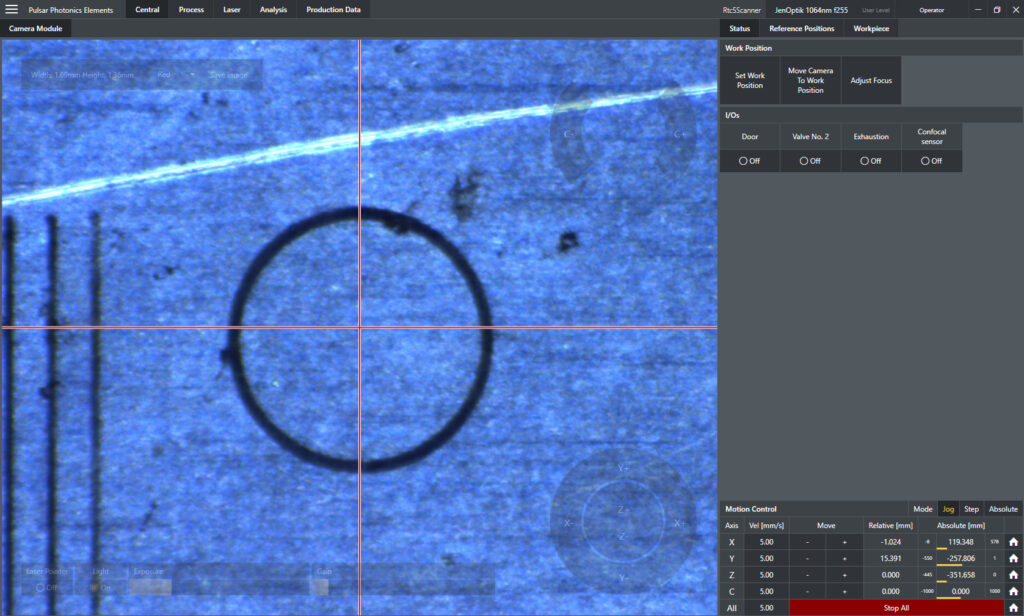

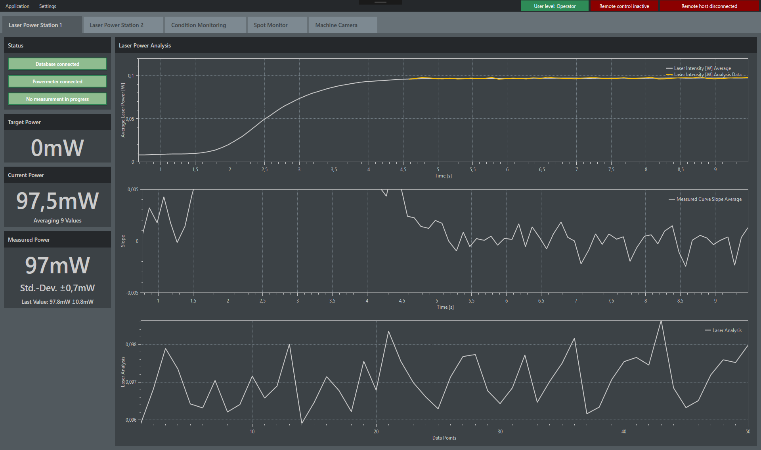

Extremely careful calibration of the free jet process

Laser micromachining stands and falls with the beam guidance from the laser to the workpiece. Dr. Ryll: “As we are dealing with high-energy radiation, guidance through fibres is currently out of the question due to the associated losses. That’s why we use the free beam to overcome this challenge.” However, because even minor angular errors in laser processing can lead to significant structural deviations, extremely precise adjustment and calibration of the scanning and coordinate devices is required. The precision of laser micromachining also depends largely on well thought-out data and heat management. It is crucial that the workstations are correctly supplied with data in real time: Real-time online monitoring is therefore central to the operation of the system. “This monitoring enables us to continuously track how and when the machine is working with certain files,” explains Dr. Ryll.

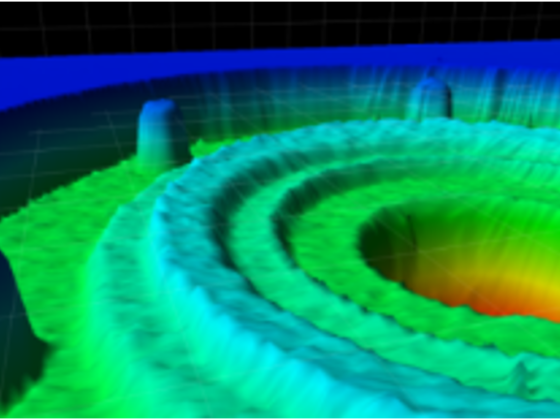

Demonstrator plate (1000 mm x 1000 mm) for large-area USP laser processing with sample structures for functional surfaces and deep engravings. © Pulsar Photonics GmbH.

Wide range of applications in XXL format

Building on this advanced development, the Fraunhofer ILT spin-off is already working in dimensions that significantly exceed ten square meters. According to the Managing Director, the aim is to develop technologies that can be used to process areas of 100 square meters or more. The demand for potential applications for laser micromachining in XXL format is high: according to Dr. Ryll, it ranges from the preparation of surfaces for bonding and coating processes to large-area tool processing and micro- and nanostructuring through to the production of large-format screens.

Dr. Joachim Ryll, Managing Director of Pulsar Photonics GmbH, is focusing on a completely new approach to large-area laser micromachining: “The aim is to develop technologies that can be used to process areas of 100 square meters or even more.”

Examples of applications are:

- Large-scale roughening and modification of surfaces in preparation for bonding and coating processes

- Large-area tool processing, e.g. for forming and shaping tools, also for the paper, film or plastics processing industry

- Large-scale micro- and nanostructuring for the production of functional surfaces

- Production of large-format screens for process engineering applications

Pulsar Photonics

Pulsar Photonics GmbH is an innovative high-tech company in the field of laser technology. The company’s range of services includes laser process technology, plant engineering with software development and the laser systems technology division.

Since its foundation, the company has been working intensively on scaling approaches for production. For customers, the company offers exclusive services ranging from professional application development and ramp-up to the construction of automatic production machines with service and know-how transfer. Pulsar Photonics is continuously investing in its own production capacities for single part and series production with (ultra) short pulse lasers. Core processes are structuring, drilling and precision cutting.

Pulsar Photonics GmbH has its headquarters in Aachen. The company was founded in 2013 as a spin-off of the Fraunhofer ILT in Aachen and was financed in its growth phase by the Hightech Gründerfonds HTGF, Bonn. Pulsar Photonics has been part of the Schunk Group since 2021.

With more than 90 employees today, the fast-growing and profitable company is a German SME and part of the LaserRegionAachen structural change initiative.

Pictures of the Press Release (Download)

Technical Contact

Dr. Marius Gipperich

Phone: +49 (0) 2405 49 504 – 28

E-Mail: machines@pulsar-photonics.de

Pulsar Photonics GmbH

Alte Würselener Str. 13

52080 Aachen

Press Contact

Sonja Wichert

Phone: +49 (0) 2405 49 504 – 36

E-Mail: info@pulsar-photonics.de

Pulsar Photonics GmbH

Alte Würselener Str. 13

52080 Aachen