Application areas of Laser micromachining

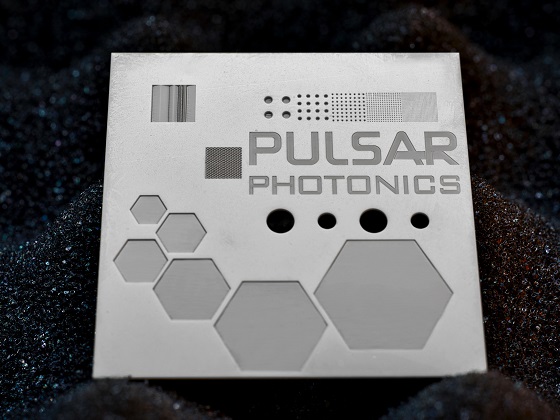

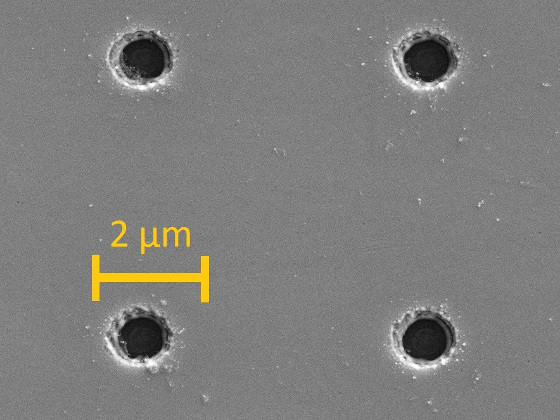

Ultrashort pulse lasers are an established tool in laser technology for micromachining components with the highest precision. Due to the outstanding characteristic properties of these lasers, there are more and more applications in the most varied areas of material processing – in particular in microstructuring, micro-drilling, fine cutting and the functionalization of surfaces.

The mostly clear quality advantages of USP processing compared to established processing methods and also known laser methods are the main reason for switching to this technology. Lateral resolutions of a few micrometers and a depth resolution of less than one micrometer allow a wide variety of applications.

What are the advantages of UKP laser processing?

Contract manufacturing for laser processing of

Ceramics, glass and plastics

Metalle, Halbleiter, Keramik, Gläser, Kunststoffe, Kompositmaterialien – der Bearbeitung von Materialien sind mit dem Ultrakurzpulslaser kaum Grenzen gesetzt. Sogar biologisches Gewebe kann behandelt werden. Für die präzise und feine Lasermikrobearbeitung hat sich die UKP Laserfertigung daher bereits am Markt durchgesetzt.

You can also benefit from the advantages of our ultrashort pulse laser production. We accompany you from application development to series production of components for your products. Use our laser contract manufacturing on self-developed machines for laser drilling, laser structuring, laser fine cutting and surface functionalization.

These industries are already benefiting from ultrashort pulse laser processing:

AREAS OF APPLICATION LASER processing

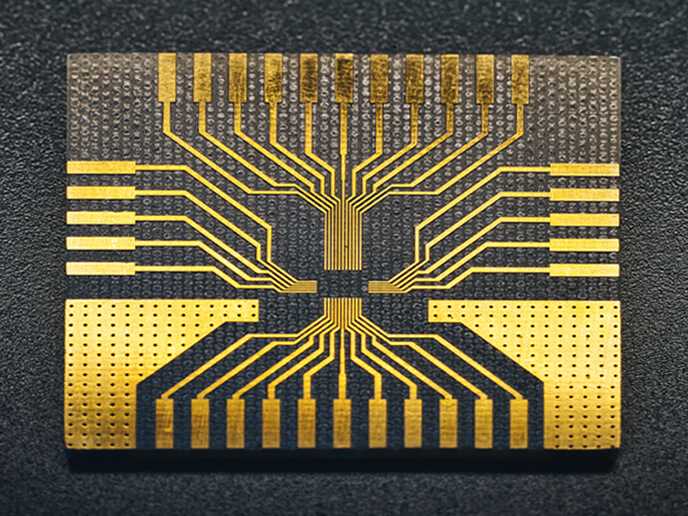

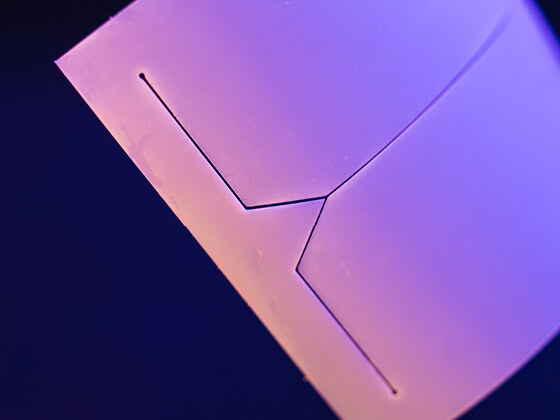

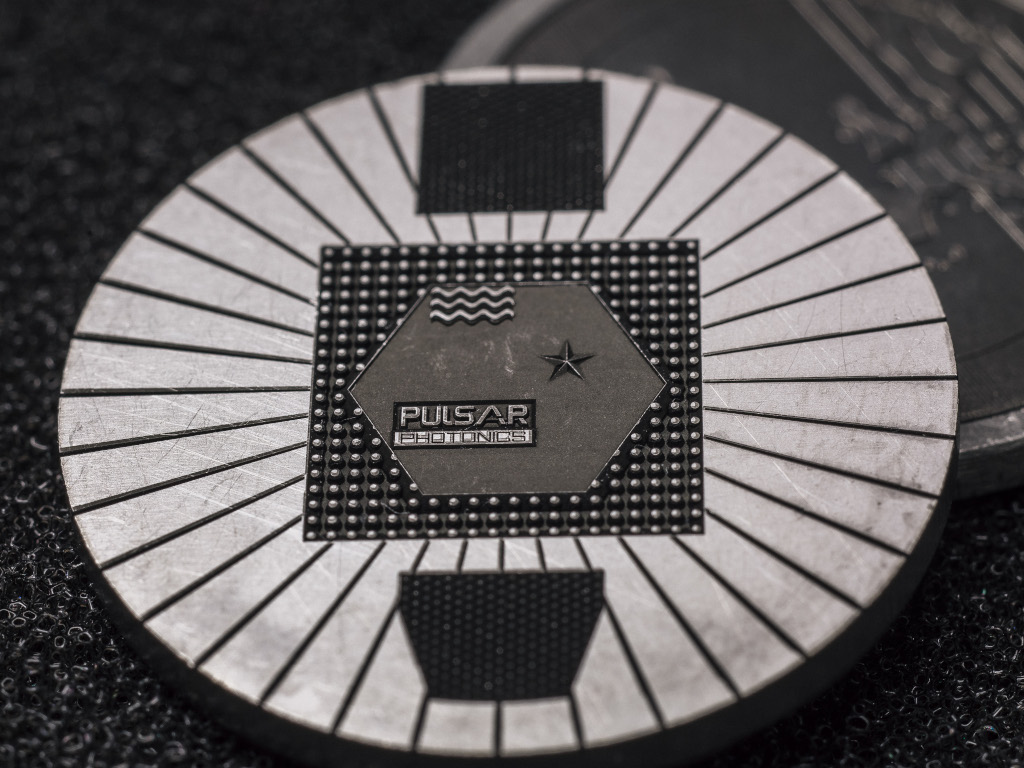

Microsieves

With laser micro-drilling, microsieves can be made from almost any material and with a high density. In selected processes, the throughput could be increased by up to a factor of 4 by using laser-drilled stainless steel sieves.

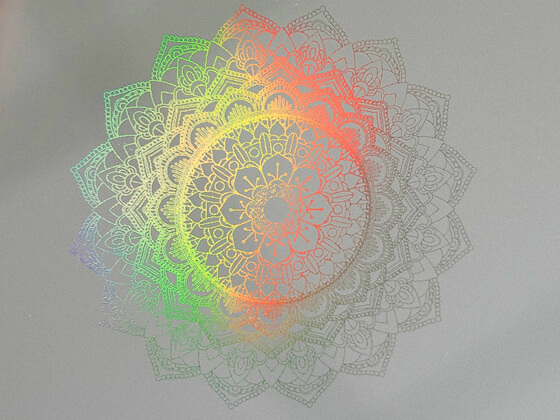

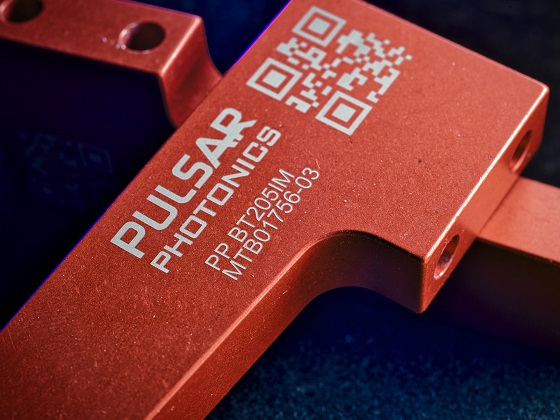

High-contrast markings

USP lasers can be used to produce corrosion-resistant, high-contrast markings in many metals. The marking takes place here by introducing a light-absorbing microstructure, which leads to a high contrast with simultaneous abrasion resistance.

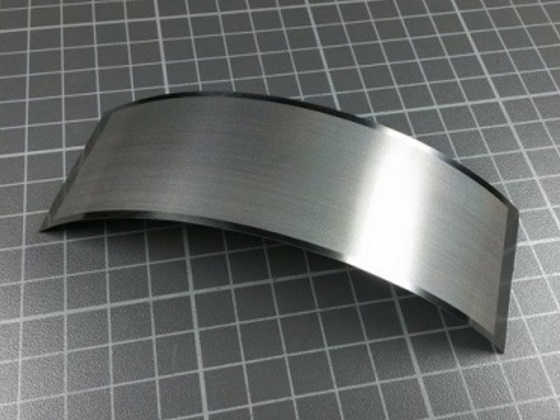

TOOL TECHNOLOGY

Laser microstructuring has increasingly established itself as a process used for tool technology. In addition to maximum flexibility in terms of geometry and materials, the main advantages are the structure sizes and surface roughness that can be achieved.

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales