Efficient large-scale system through parallelization with multi-scanner and multi-beam processing

Modular design with a processing area of up to 2500 mm x 1500 mm each

Scalability to full-surface laser micromachining of > 10 m² in size

THE LASER MACHINE FOR FULL-SURFACE LASER PROCESSING OF LARGE FLAT COMPONENTS

The variety of applications for laser micromachining is becoming increasingly interesting for really large surfaces as the available power of laser beam sources increases into the kW range.

Motivated by environmental requirements or regulations restricting the use of chemicals or paints, more and more companies are faced with the task of converting their production processes to more environmentally friendly and/or less energy-intensive manufacturing methods.

Large-area laser micromachining offers a way to replace existing manufacturing processes or to improve coating and cleaning processes. The laser-based manufacturing process also opens up scope for new product features and market differentiation thanks to the digital process chain and the combinability of laser processes.

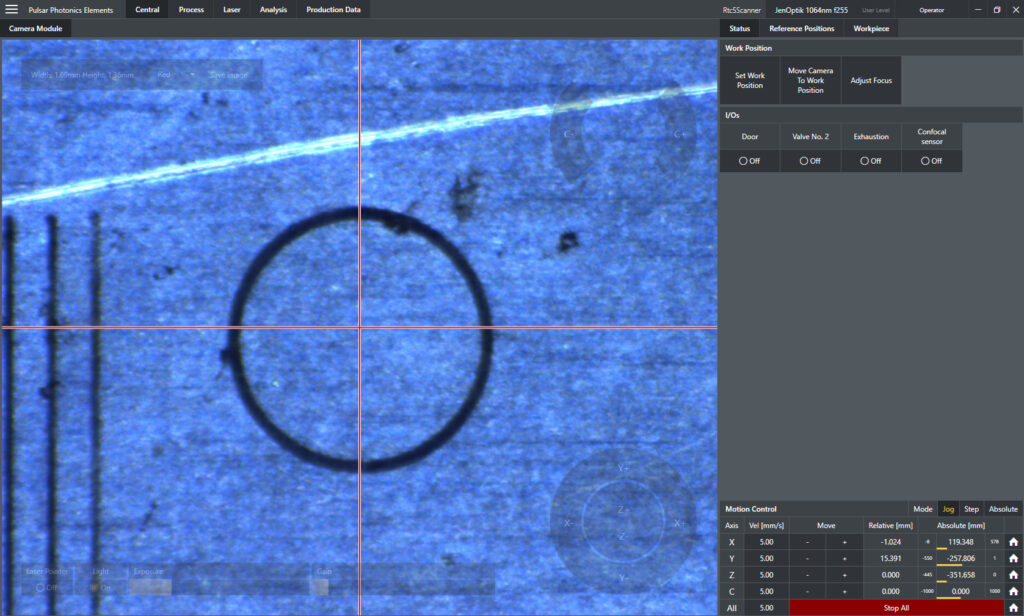

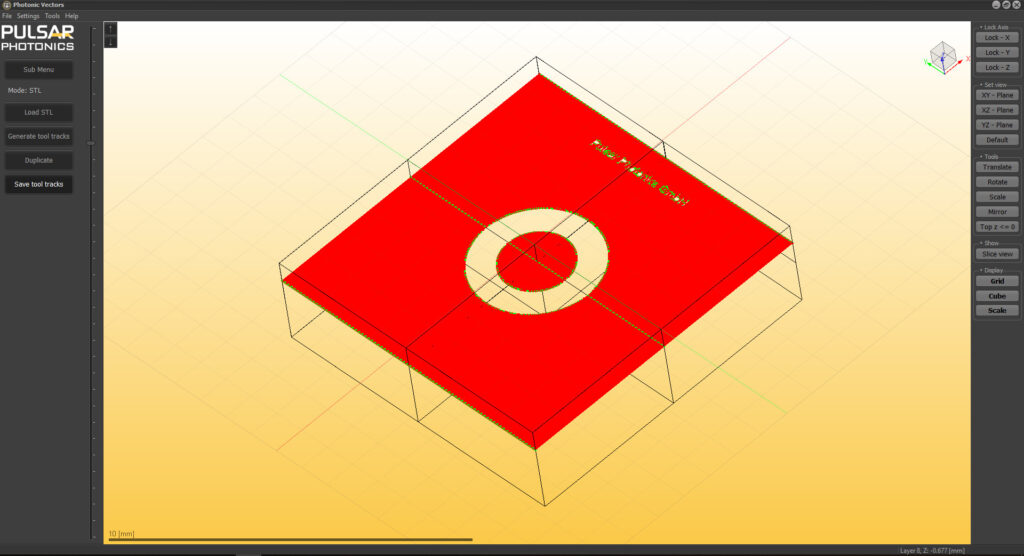

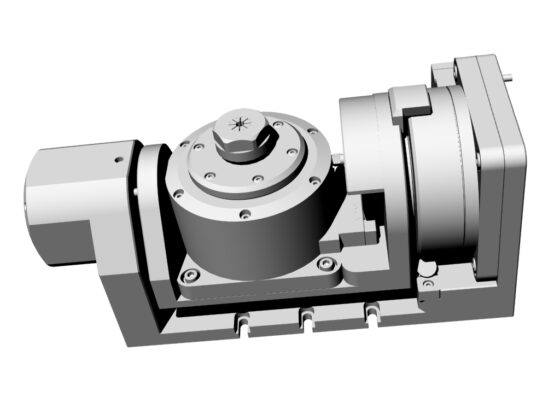

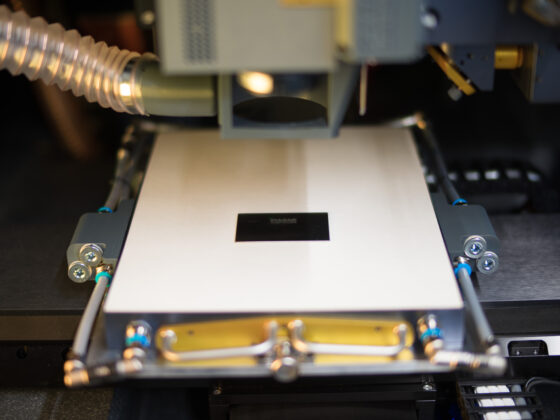

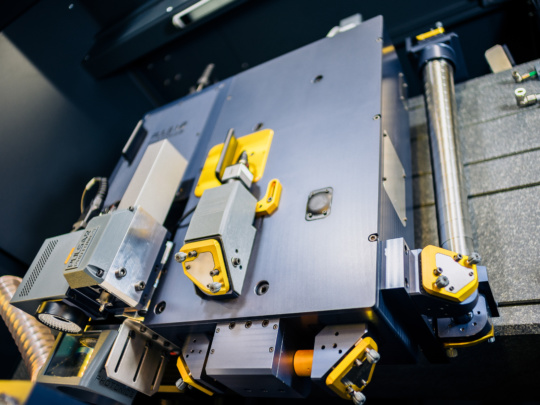

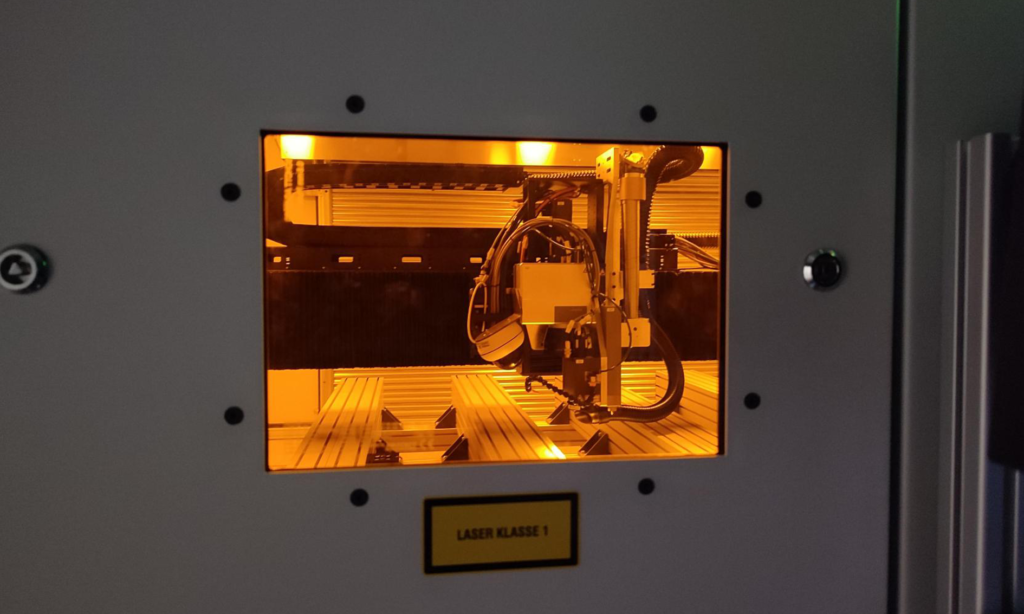

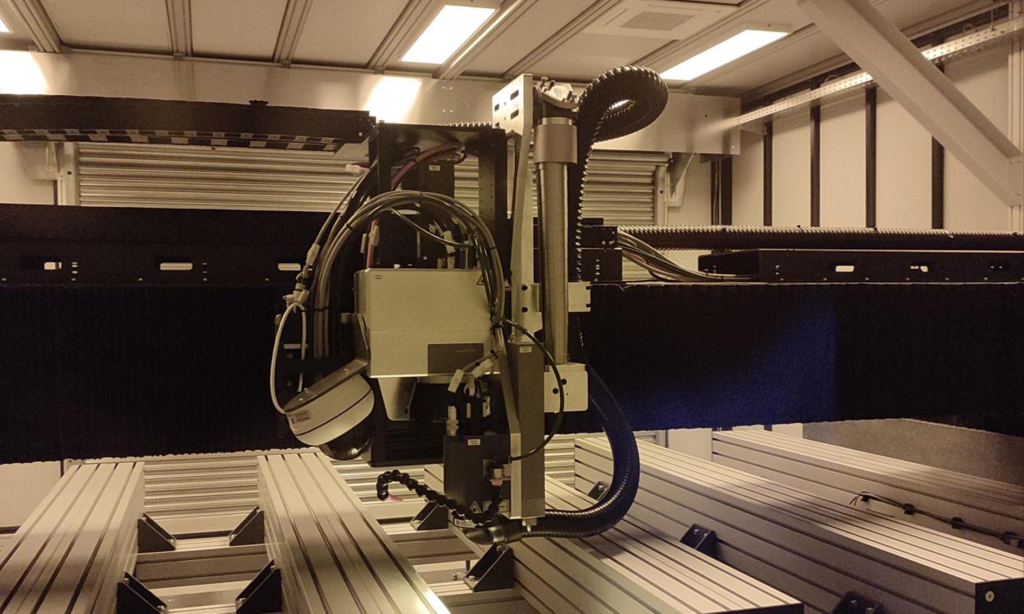

With the RDX2800 laser machine, Pulsar Photonics is setting new standards in the laser micromachining of large flat components. Designed as a modular gantry system with a holder for large flat components with dimensions of up to 2,500mm x 1,500mm per machine module, the system can achieve full-surface laser micromachining on square meter-sized surfaces, even with ultrashort pulse lasers.

The machine system has a modular design and can be assembled from several machine modules. This means that it is also possible to process larger components with surfaces significantly larger than 10 m².

The RDX2800 thus provides a platform with which large-area laser micromachining processes can be realized on an industrial scale.

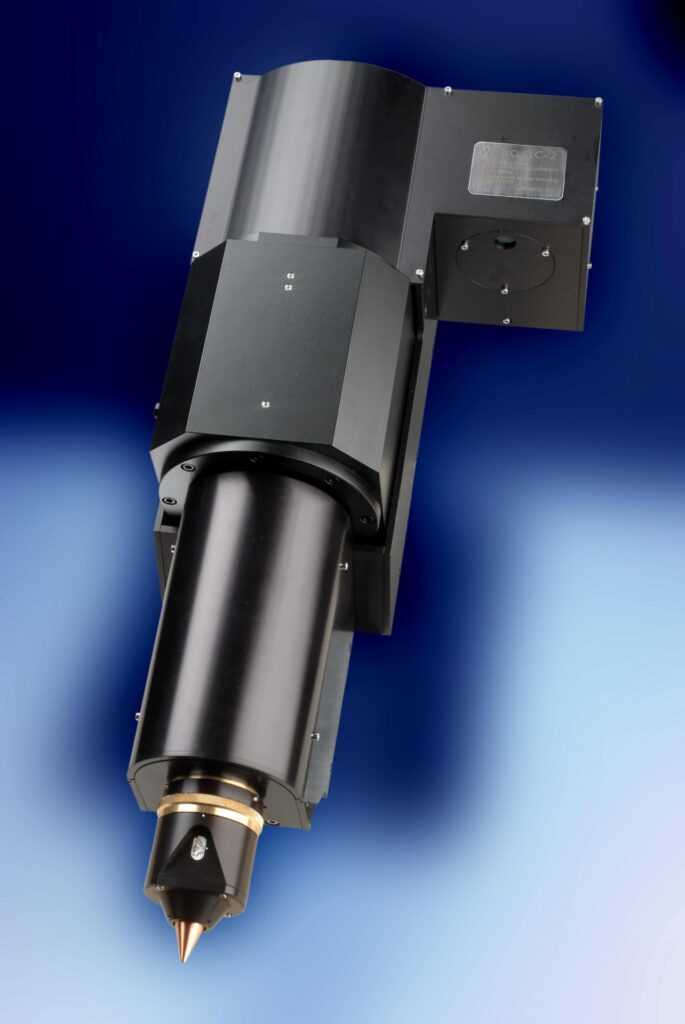

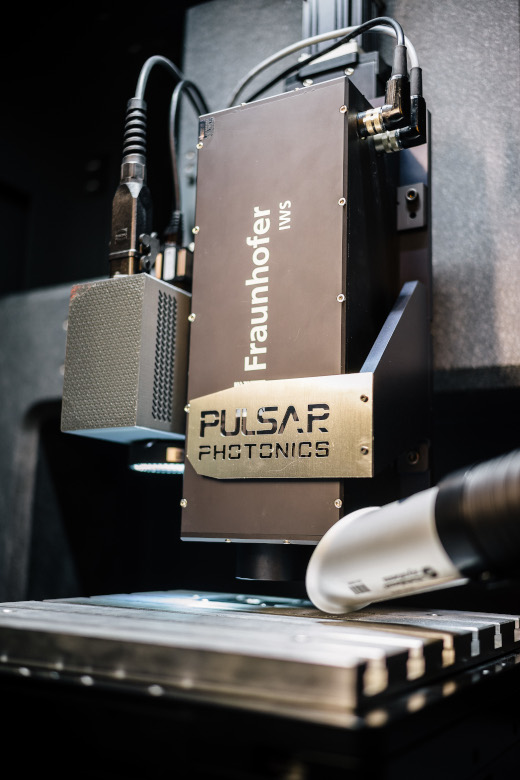

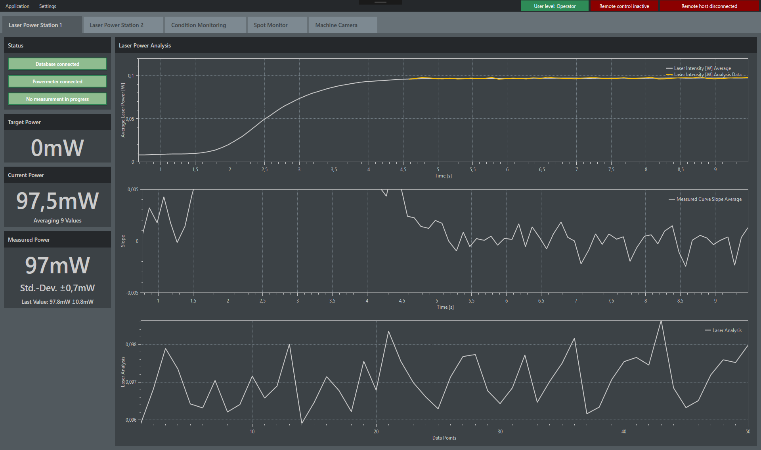

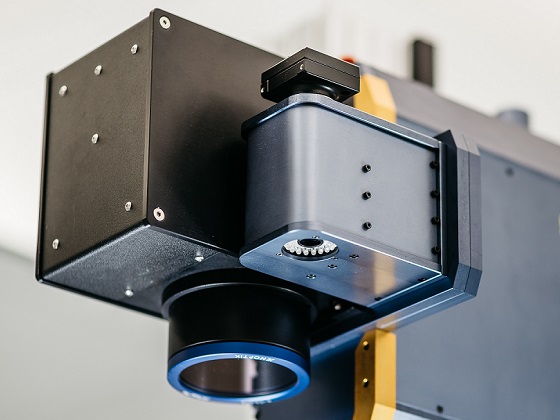

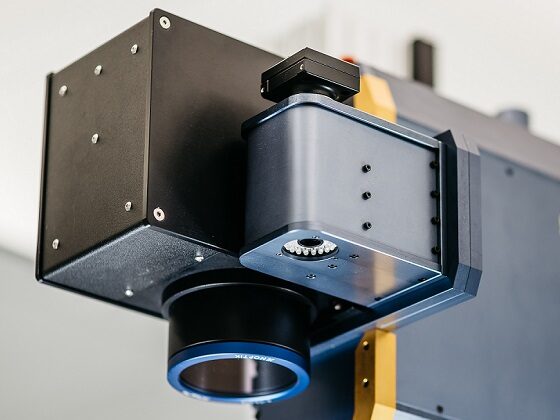

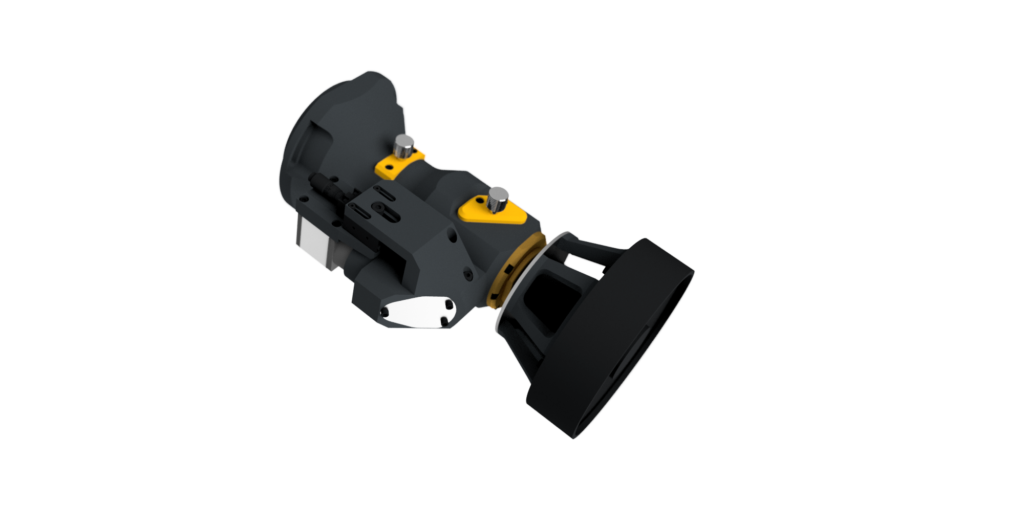

The RDX2800 is based on scaling the processing speed by using several processing heads – also in combination with multi-beam processing. This means that USP laser processes can also be realized economically on large surfaces.

With regard to the selection of the number and type of processing heads and laser beam sources, the system has a modular design to meet the requirements of the laser process.

Together with our customers, it is therefore possible to tailor the machine in terms of productivity and process quality.

Examples of applications

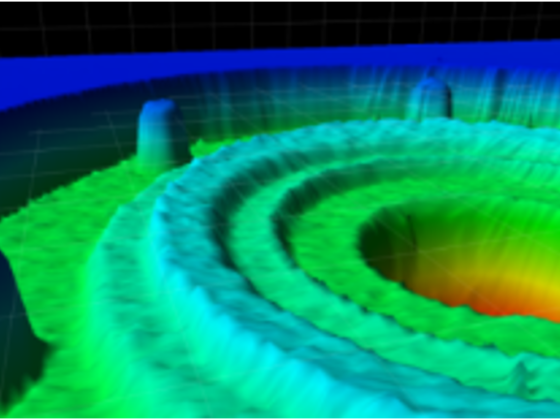

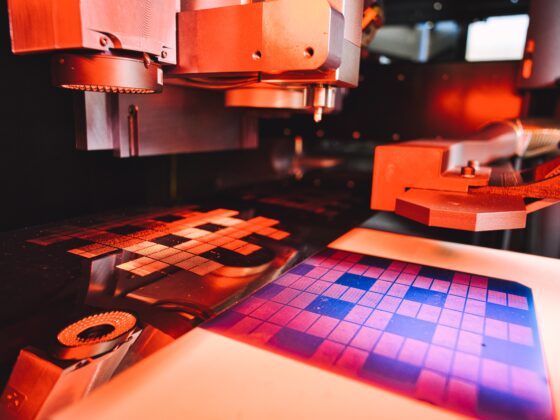

- Large-scale roughening and modification of surfaces in preparation for bonding and coating processes

- Large-area tool processing, e.g. for forming and shaping tools, also for the paper, film or plastics processing industry

- Large-scale micro- and nanostructuring for the production of functional surfaces

- Production of large-format screens for process engineering applications

Gallery

Your Personal Contact person

Dr. Marius Gipperich

Technical Sales